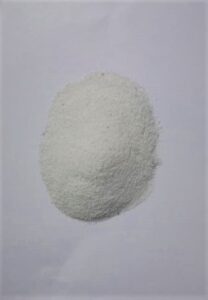

Barite, a naturally occurring mineral composed primarily of barium sulfate (BaSO₄),

plays a crucial role in the chemical production industry. Known for its high purity and excellent quality, barite serves as a vital raw material in the manufacture of various chemicals. This article explores how barite enhances purity and quality in chemical production and its applications across different sectors. Barite Usage in Purity and Quality in Chemical Production

What is Barite?

Barite is a dense, non-metallic mineral with a high specific gravity and chemical inertness. It is primarily mined and processed for its barium content, which is essential in various industrial applications. The mineral is found in many geological formations and is available in different grades, making it versatile for multiple uses in the chemical industry. Barite Usage in Purity and Quality in Chemical Production

Importance of Barite in Chemical Production

1. High Purity Levels

One of the most significant advantages of using barite in chemical production is its high purity level. High-purity barite contains minimal impurities, ensuring that the final products meet stringent quality standards. This characteristic is especially critical in industries such as pharmaceuticals and food processing, where product safety and efficacy are paramount.

2. Consistency in Quality

Barite’s inherent properties allow for consistent quality in the production of barium-based chemicals. Its stability during chemical reactions leads to predictable outcomes, making it an ideal choice for manufacturers seeking reliable raw materials. This consistency is vital for applications that require precise formulations, such as in the production of pigments and specialty chemicals.

https://iranmineral.net/is-barite-powder-toxic/

3. Chemical Stability

Barite exhibits excellent chemical stability, making it resistant to various environmental factors. This stability ensures that the properties of barite remain unchanged during storage and processing, reducing the risk of contamination. As a result, manufacturers can trust that their barium compounds will perform as expected, maintaining high standards in their final applications.

Applications of Barite in Chemical Production

1. Barium Compounds Manufacturing

Barite serves as the primary source for producing various barium compounds, including barium carbonate (BaCO₃), barium chloride (BaCl₂), and barium hydroxide (Ba(OH)₂). These compounds have diverse applications across industries, from glass and ceramics to electronics and pharmaceuticals. The use of high-purity barite ensures that these compounds meet the required specifications for each application.

2. Pigments and Coatings

In the pigments and coatings industry, barite is widely used as a filler and extender. Its high opacity and whiteness enhance the quality of paints, coatings, and inks. By incorporating high-quality barite, manufacturers can improve the durability and aesthetic appeal of their products while ensuring that they comply with environmental regulations.

3. Pharmaceuticals

Barite is used in the pharmaceutical industry, particularly as a contrast agent in medical imaging. High-purity barite sulfate is utilized in X-ray and CT imaging to enhance the visibility of the gastrointestinal tract. The purity of the barite used in this application is critical to patient safety and the accuracy of diagnostic results.

Iran Mineral Company