- Large bentonite resources in the world (number of existing reserves)

- First, I need to list the top countries with significant bentonite deposits. The US, especially Wyoming, is a big producer. Iran, China, and India also have large reserves. Russia, Turkey, and some European countries like Greece and Germany come to mind. Maybe Brazil and Mexico in Latin America too.

- Next, I should mention the estimated global reserves. From what I remember, it’s around 2.5 to 3 billion metric tons. But I need to check if these numbers are up to date. The user wants current data, so perhaps I should note that the figures are approximate as of 2023.

- Then, for each country, specify the regions. For the US, Wyoming’s sodium bentonite is key. China has Inner Mongolia and Xinjiang. India’s Gujarat and Rajasthan. Russia’s Ural Mountains and Siberia. Turkey’s Ankara and Edirne. Greece’s Milos Island. Germany’s Bavaria. Brazil’s Paraíba and Bahia, Mexico’s San Luis Potosí.

- Also, it’s important to highlight the types of bentonites each region is known for, like sodium vs. calcium. The US and Turkey have high-swelling sodium bentonite, which is valuable for industrial uses. China and India have both types.

- I should structure the answer clearly, maybe using bullet points for countries and their regions. Add a section on global reserves and another on key points. Make sure to mention the leading producers and their specific deposits. Also, note the economic factors like mining activity and market demand influencing reserves.

- Need to keep the answer concise but informative, avoiding technical jargon. Ensure the user gets a clear overview of where bentonite is found, the types available, and the scale of reserves. Check for any recent data changes, but since I don’t have real-time updates, use the latest available info up to 2023. Finally, remind the user that exact figures can vary and are subject to discoveries or mining activities.

- How bentonite is formed in nature

- Bentonite is a type of natural clay formed from the alteration of volcanic ash and is mainly made of the mineral montmorillonite (from the smectite group).

- : Key Features

- Lamellar Structure: Ability to absorb water and swell (sodium: high swelling; calcium: lower swelling)

- Adhesion and Plasticity: Ability to be molded and glued in the presence of water

- Ion Adsorption: Ion exchange to remove impurities

- 4- Main Types of Bentonite:

- Sodium Bentonite: High swelling, used in well drilling, dam construction, and sealing.

- Calcium Bentonite: Low swelling, used in the foundry, oil refining, and agricultural industries

- Types of bentonites

Types of Bentonites (based on dominant exchangeable ions and applications):

- Sodium Bentonite (Swelling Bentonite):

– Dominant Ion: (Na⁺)

– Key Property: High swelling capacity (up to 15–20 times its dry volume when hydrated).

– Applications:

– Drilling industries: Primary component of drilling muds (lubricates and seals boreholes).

– Dam construction and waterlogging: Used in landfill liners, pond sealing, and waterproofing.

– Everyday uses: Cat litter, cosmetics (e.g., face masks).

- Calcium Bentonite (Non-Swelling Bentonite):

– Dominant Ion: (Ca²⁺)

– Key Property: Limited swelling capacity but high adsorption and plasticity.

– Applications:

– Casting: Binds sand in foundry molds.

– Purification: Clarifies oils, wines, and juices by removing impurities.

– Agriculture: Soil conditioner to retain moisture and nutrients.

- Potassium Bentonite (Illite):

– Dominant Ion: (K⁺)

– Key Property: Lower swelling compared to sodium bentonite.

– Applications:

– Mostly used in Ceramic manufacturing and as a minor component in agricultural amendments.

- Activated Bentonite (Acid-Activated):

– Process: Treated with sulfuric or hydrochloric acid to enhance adsorption properties.

– Applications:

– Oil and grease purification: Removes contaminants in industrial processes.

– Food industries: Bleaching agent for edible oils.

- Organoclay (Organically Modified Bentonite):

–Process: Chemically modified with organic compounds (e.g., quaternary ammonium salts).

– Key Property: Hydrophobic (water-repellent) and compatible with organic polymers.

– Applications:

– Paint & plastic industry: Thickening agent in paints, coatings, and adhesives.

– Environmental: Absorbs oil and organic pollutants in spill cleanup.

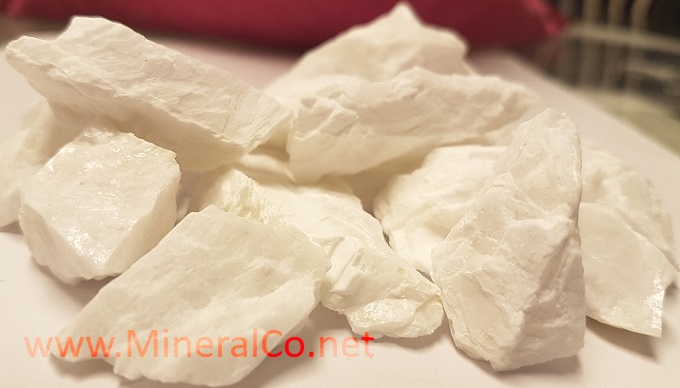

- Non treated bentonite

This kind of bentonite is very special & is not available everywhere.

| Analyze tested by the lab

|

Non treated Bentonite

| Θ600 | Θ300 | PV | YP | Ratio YP/PV | |

| Sample 1 | 112 | 75 | 37 | 38 | 38/37 ≃ 1.03 |

| Sample2 | 121 | 82 | 39 | 43 | 43/39 ≃ 1.09 |

| Sample3 | 107 | 71 | 36 | 35 | 35/36 ≃ 0.97 |

| Sample4 | 103 | 68 | 35 | 33 | 33/35 ≃ 0.97 |

Client’s requirement

| Properties | Standard | API 10 |

| Yield point-plastic viscosity ratio | Maximum 1.5 | 1.07 |

| Dispersed plastic viscosity | Minimum 10 | 26 |

| Dispersed filtrate volume | Maximum 12.5mL | 9.2 |

Water loss test in untreated bentonite using API method

- Dissolve 22.5 grams of bentonite in 350 cc of distilled water and stir it with a mixer for 20 minutes.

Then:

- We put filter paper under a filter press machine for half an hour, applying a pressure of 100 PSA, and for half an hour, it starts to lose water.

- The water loss should be below 12.5 cc, which would be a good estimate, and the lower the better.

- Other Classifications:

– Natural vs. Processed:

–Natural: Mined directly (e.g., sodium or calcium bentonite).

– Processed: Enhanced for specific uses (e.g., activated, powdered, or granular forms).

– Based on color:

– White Bentonite: High purity, used in cosmetics and pharmaceuticals.

– Yellow/Green Bentonite: Common in industrial applications.

Note: Sodium and calcium bentonite are the most commercially significant types, accounting for over 90% of global production.

- Safety Notes:

- Non-toxic and safe for industrial and health use, but its dust may cause movement.

- Sulphur Bentonite:

- Sulphur Bentonite is an absorbent aluminum phyllosilicate clay consisting mostly of montmorillonite. Sulphur Bentonite, is a yellow brown pastille.

Market Analysis and Insights: Global Sulphur Bentonite Market

The global Sulphur Bentonite market was valued at US$ 161.1 million in 2020 and it is expected to reach US$ 277.7 million by the end of 2029, growing at a CAGR of 8.1% during 2021-2029.

Segment by Type:

Product Name: Sulphur Bentonite

Chemical Formula: S8

Sulphur-90%

Others (Sulphur-85% etc.)

Sulfur Content: 90% elemental sulfur content, providing a high-concentration sulfur source

Appearance: Spherical granules, typically yellow to brown, coated with bentonite

Segment by Application

Oilseeds

Cereals and Crops

Fruits and Vegetables

Others

Production by Region

United States, India, Middle East, South Korea, Australia, Iran, Uzbekistan

- Consumption by Region

North America, U.S., Canada, Europe, Germany, France, U.K, Italy, Russia, Asia-Pacific, China, Japan, South Korea, India, Iran, Australia, Taiwan, Indonesia, Thailand, Malaysia, Philippines, Vietnam, Latin America, Mexico, Brazil, Argentina, Middle East & Africa, Turkey, Saudi Arabia, U.A.E

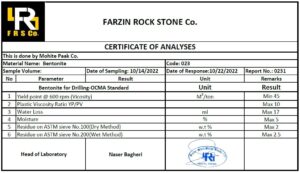

API Certificate of Analysis for Bentonite for oil well drilling (Lab No: 956B)

Bentonite Material Safety Data Sheet

(MSDS)

HAZARDS IDENTIFICATION

super white bentonite

bentonite OCMA analyzeEYE: Abrasion injuries are possible if safety glasses are not worn. Eye contact with mineral sands may irritate with discomfort,

tearing, and blurring of vision.

SKIN: Abrasion injuries are possible during blasting operations or similar exposure, with high-velocity direct exposure to skin.

INGESTION: N/A

INHALATION: The product, as shipped, does not pose any inhalation health hazard because it contains essentially no particles in

the respirable size range. However, if during handling or use, the particles are broken down to a size that can be inhaled, the

dust may be harmful to the respiratory system.

MSDS: DuPont Starblast Ultra Blasting Abrasive: Page 2 of 4

CHRONIC EFFECTS: The predominant effect of overexposure to airborne quartz in humans is silicosis. Silicosis is a chronic disease

characterized by the formation of silica-containing scar tissue in the lungs with symptoms of coughing, dyspnea, wheezing, and

nonspecific respiratory ailments. Very high short exposures to crystalline silica may lead to fatality from gross overexposure. Individuals

with preexisting diseases of the lungs may have increased susceptibility to the toxicity of excessive exposures. Several recent

epidemiology studies have shown, that in addition to silicosis, there is limited evidence of an excess of lung cancer in occupations

involving exposures mainly to crystalline silica, such as stone cutters and granite industry workers. Occupational exposures at the

recommended AEL of 0.1 mg/m³ should protect workers from silicosis and lung tumors. Respiratory illness as a result of long-term

exposure to particulates is possible. NIOSH-approved particulate respirators should be used during blasting operations.

CARCINOGENICITY INFORMATION: The following components are listed by IARC, NTP, OSHA, or ACGIH as carcinogens.

FIRST-AID MEASURES

SIGNS AND SYMPTOMS OF EXPOSURE

EYE: Irritation with discomfort, tearing, and blurring of vision

SKIN: Abrasion, redness

INGESTION: N/A

INHALATION: Coughing, shortness of breath

FIRST AID PROCEDURES

EYE: In case of contact, immediately flush your eyes with plenty of water for at least 15 minutes. Call a physician.

SKIN: Follow procedures appropriate to abrasion injuries. The compound is not hazardous by skin contact, but removal of

particles and cleansing of the skin after use is advisable.

INGESTION: No specific intervention is indicated as the compound is not hazardous by ingestion. However, if symptoms occur,

consult a physician.

INHALATION: If inhaled, immediately remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give

oxygen. Call a physician.

FIRE FIGHTING MEASURES

FLAMMABLE PROPERTIES: Nonflammable

FLASH POINT / METHOD USED: None

AUTOIGNITION: None

FLAMMABILITY LIMITS (% by volume in air): LEL: N/A UEL: N/A

EXTINGUISHING MEDIA: As appropriate for combustibles in the area.

NFPA RATINGS: Health 0; Flammability 0; Reactivity 0.

FIRE FIGHTING INSTRUCTIONS: None

COMBUSTION PRODUCTS: None

ACCIDENTAL RELEASE MEASURES

PERSONAL PRECAUTIONS: Respiratory protection: NIOSH-approved respiratory equipment for abrasive blast environments or

when handling respirable dust. Personal protection: NIOSH-approved garments and headgear during blasting operations. See

Section 8. Wash thoroughly after handling. Note: Review FIRE FIGHTING MEASURES (Section 5) and HANDLING AND STORAGE

(Section 7) before proceeding with clean up. Use appropriate personal protective equipment during clean-up.

CLEANUP MEASURES: Sweep up the spillage.

HANDLING AND STORAGE

NORMAL STORAGE: General dry storage, ambient air temperature, and pressure.

HANDLING: Avoid breathing dust. Wash thoroughly after handling. If handling respirable dust (flour), use of gloves and washing

before eating, drinking, applying cosmetics, or smoking is advisable to minimize dust inhalation from hands.

EXPOSURE CONTROLS / PERSONAL PROTECTION

ENGINEERING CONTROLS: Use sufficient ventilation to keep employee exposure below the recommended limits. If using this product

as an abrasive blast agent in confined areas, airborne dust levels should be controlled by the physical enclosure of the abrasive blasting

operation. The enclosure should be exhaust ventilated by 29 CFR 1910.94 Ventilation (a) Abrasive Blasting.

RESPIRATORY PROTECTION: A NIOSH / MSHA-approved air purifying respirator with a particulate cartridge or canister may be

permissible under certain circumstances where airborne concentrations are expected to exceed exposure limits. The protection

provided by air-purifying respirators is limited. Use a NIOSH / MSHA-approved positive pressure air-supplied respirator if there is

any potential for an uncontrolled release, exposure levels are unknown, or any other circumstances where air-purifying respirators

may not provide adequate protection. For abrasive blasting use a continuous flow airline respirator covering the head, neck, and

shoulders to protect rebound abrasive per 29 CFR 1910.94 (a) (5).

EYE AND FACE PROTECTION: Wear safety glasses with side shields.

SKIN AND HAND PROTECTION: In handling, gloves as desired by the user. In use, wear impervious clothing, such as gloves, apron,

boots, or whole-body suit, as appropriate.

PHYSICAL AND CHEMICAL PROPERTIES

PHYSICAL DESCRIPTION: Reddish brown solid, free-flowing sand

ODOR: Odorless FLASH POINT: None

VAPOR PRESSURE (mm Hg): Not volatile VAPOR DENSITY (AIR = 1): Not volatile

BOILING POINT: N/A EVAPORATION RATE (BUTYL ACETATE = 1): Not volatile

MELTING POINT: 1370°C (2500°F) SOLUBILITY: Insoluble in water

SPECIFIC GRAVITY (H2O = 1): 3.7 pH: N/A

STABILITY AND REACTIVITY

CHEMICAL STABILITY: Stable

CONDITIONS TO AVOID: None

INCOMPATIBILITY WITH OTHER MATERIALS: None reasonably foreseeable

HAZARDOUS DECOMPOSITION PRODUCTS: Decomposition will not occur

HAZARDOUS POLYMERIZATION: Polymerization will not occur

TOXICOLOGICAL INFORMATION

CARCINOGENICITY: If during handling or use, the particles are broken down to a size that can be inhaled, the dust may be

harmful to the respiratory system. Staurolite products may contain up to 5% quartz. The predominant effect of overexposure to

airborne respirable quartz in humans is silicosis. Silicosis is a chronic fibrotic lung disease characterized by the formation of

silica-containing scar tissue in the lungs with symptoms of coughing, dyspnea, wheezing, and nonspecific respiratory ailments.

Gross acute overexposure to quartz by inhalation may cause fatality. Epidemiological studies show that in addition to silicosis

there is limited evidence of excess lung cancer in occupations involving exposures mainly to respirable quartz, such as stone

cutters and granite industry workers.

LISTED CARCINOGEN BY: IARC, NTP

ANIMAL DATA: Quartz: Oral ALD: >11,000 mg/kg in male rats.

Quartz is not a skin irritant or a skin sensitizer in animals but is a mild eye irritant. Single doses of 50 mg quartz administered by

intratracheal instillation have resulted in pulmonary fibrosis at 60- and 120-days post-exposure in rats. Repeated and chronic

exposures as low as 0.7 mg instillation and 12 mg/m³ by inhalation resulted in pulmonary fibrosis, inflammation, edema, and

emphysema in animals exposed to quartz. Lung tumors were observed in rats exposed for up to two years by inhalation to 12.4

or 51.6 mg/m³ quartz. Lung tumors were also observed in rats exposed to quartz by intratracheal instillation. Silica was positive

in mammalian cell cultures for cell transformation and chromosomal effects. It was negative in cell culture assays for gene

mutation in bacteria and DNA damage in mammalian cells and in a whole animal assay for chromosomal effects. No animal test

reports are available to define developmental, or reproductive toxicity.

DISPOSAL CONSIDERATIONS

Treatment, storage, transportation, and disposal must be by applicable federal, state/provincial, and local regulations.

If approved, may be transferred to a land disposal site. If the spent grit contains contaminates at levels above those

specified under RCRA, then the waste is defined as hazardous and must be managed per federal or state regulations governing

hazardous waste.

Transport Information

DOT Classification: Not a DOT-controlled material (United States).

Identification: Not applicable.

Special Provisions for Transport: Not applicable.

Other Regulatory Information

Federal and State Regulations: TSCA 8(b) inventory: Bentonite

Other Regulations: OSHA: Hazardous by definition of Hazard Communication Standard (29 CFR 1910.1200).

Other Classifications:

- 5

WHMIS (Canada): CLASS D-2A: Material causing other toxic effects (VERY TOXIC).

DSCL (EEC): R36- Irritating to eyes.

HMIS (U.S.A.):

Health Hazard: 2

Fire Hazard: 0

Reactivity: 0

Personal Protection: E

National Fire Protection Association (U.S.A.):

Health: 2

Flammability: 0

Reactivity: 0

Specific hazard:

Protective Equipment:

Gloves. Lab coat. Dust respirator. Be sure to use an approved/certified respirator or equivalent. Wear an appropriate respirator

when ventilation is inadequate. Splash goggles.

Other Information

References: Not available.

Other Special Considerations: Not available.

Created: 10/10/2005 08:14 PM

Last Updated: 06/11/2012 12:00 PM

The information above is believed to be accurate and represents the best information currently available to us. However, we

make no warranty of merchantability or any other warranty, express or implied, concerning such information, and we assume

no liability resulting from its use. Users should make their investigations to determine the suitability of the information for

their particular purposes. In no event shall ScienceLab.com be liable for any claims, losses, or damages of any third party or for

lost profits or any special, indirect, incidental, consequential, or exemplary damages, howsoever arising, even if ScienceLab.com

has been advised of the possibility of such damages.

Bentonite for Ceramic usage analyze

Packing in 1& 1.5 T jumbo bag