A Key Mineral for Coatings and Pigments

The Role of Bentonite in the Paint Industry

Bentonite is a versatile natural clay widely used in industrial applications, including paints and coatings. Due to its exceptional absorbent, thickening, and stabilizing properties, bentonite is a crucial ingredient in high-performance paints, primers, and industrial coatings. Bentonite for Painting

This article explores how bentonite is used in painting, its chemical properties, its benefits in paint formulations, and the leading producers of bentonite for the paint industry. Bentonite for Painting

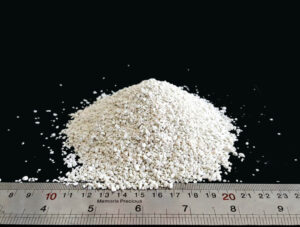

What is Bentonite?

Bentonite is a naturally occurring clay composed primarily of montmorillonite, a type of phyllosilicate mineral. It forms from the weathering of volcanic ash and is rich in aluminum, magnesium, and iron.

There are two primary types of bentonite:

- Sodium Bentonite – High swelling capacity, mainly used in drilling fluids, sealants, and industrial applications.

- Calcium Bentonite – Lower swelling ability, commonly used in paints, cosmetics, and pharmaceuticals.

For the paint industry, modified calcium bentonite is preferred because it enhances paint texture, stability, and durability.

How is Bentonite Used in Paints and Coatings?

1. Rheology Modifier and Thickening Agent

Bentonite is used in paints as a rheology modifier, helping to control viscosity and consistency.

- Prevents paint separation during storage.

- Improves spreadability and brushability.

- Enhances paint suspension, keeping pigments evenly distributed.

2. Pigment Suspension and Stability

Bentonite acts as a suspension agent, preventing pigments from settling at the bottom of the paint can.

- Ensures color uniformity during application.

- Prevents clumping and streaking in liquid paints.

- Extends paint shelf life by maintaining stability.

3. Anti-Sagging and Anti-Drip Properties

Bentonite improves paint application by preventing drips and sags when applied to vertical surfaces.Bentonite for Painting

- Helps maintain smooth, even layers of paint.

- Reduces the need for multiple coats, saving time and resources.

- Works in both water-based and solvent-based paints.

4. Improves Paint Durability and Adhesion

Adding bentonite to paint enhances surface adhesion and wear resistance.

- Helps paint stick better to walls, wood, and metal surfaces.

- Increases resistance to cracking, peeling, and chipping.

- Ensures long-lasting color vibrancy and weather protection.

5. Eco-Friendly and Non-Toxic Additive

Bentonite is a natural, non-toxic mineral, making it ideal for eco-friendly and low-VOC (volatile organic compound) paints.

- Used in biodegradable and sustainable paint formulas.

- Does not emit harmful fumes or odors.

- Safe for indoor applications and children’s rooms.

Types of Paints That Use Bentonite

1. Water-Based Paints (Latex Paints)

- Used in interior and exterior wall coatings.

- Enhances smooth application and drying time.

- Improves color retention and resistance to fading.

2. Oil-Based Paints and Varnishes

- Found in wood coatings, furniture paints, and industrial finishes.

- Helps control flow properties for a uniform finish.

- Prevents oil separation and pigment settling.

3. Industrial Coatings and Protective Paints

- Used in automotive, marine, and metal coatings.

- Provides chemical resistance and protection against corrosion.

- Enhances weatherproofing and UV resistance.

4. Textured and Decorative Paints

- Used in artistic and textured wall coatings.

- Adds thickness and body to the paint.

- Improves visual appeal and customization options.

Benefits of Using Bentonite in Paints

✔ Enhanced Paint Stability

Prevents clumping, streaking, and pigment separation, ensuring consistent quality.

✔ Improved Workability and Application

Makes paint smoother, easier to apply, and resistant to sagging.

✔ Cost-effective and Readily Available

Bentonite is an affordable mineral, reducing overall paint production costs.

✔ Eco-Friendly and Non-Toxic

Supports the production of sustainable, low-VOC paints for a healthier environment.

✔ Increased Paint Durability

Enhances weather resistance, adhesion, and longevity.

Leading Producers of Bentonite for Paints

Several countries are major producers of high-quality bentonite used in the paint and coatings industry.

1. United States: The Largest Bentonite Producer

The United States is the world’s leading producer of bentonite, with large deposits concentrated in Wyoming, Montana, Texas, and South Dakota. The U.S. bentonite industry is known for its high-purity sodium bentonite, used in paint formulations, drilling fluids, and industrial applications.

Key U.S. Bentonite Suppliers for Paints

1.1 AMCOL International (Minerals Technologies Inc.)

- One of the largest global suppliers of bentonite.

- Produces high-quality bentonite-based additives for paints and coatings.

- Exports to Europe, Asia, and South America.

1.2 Wyo-Ben Inc.

- Specializes in high-yield sodium bentonite used in paint thickeners and stabilizers.

- Has processing plants in Wyoming and Montana.

1.3 Black Hills Bentonite

- Supplies processed bentonite for paints, coatings, and industrial applications.

- Focuses on low-dust, fine-milled bentonite for better dispersion in paint formulas.

Why U.S. Bentonite is Preferred for Paints?

High-purity sodium and calcium bentonite.

Advanced processing techniques for fine-milled powders.

Consistent supply chain and high production capacity.

2. China: A Major Supplier of High-Quality Bentonite

China is one of the largest exporters of bentonite, with deposits in Inner Mongolia, Xinjiang, and Henan provinces. Chinese manufacturers produce calcium bentonite for paint formulations, providing cost-effective and fine-grade options.

Key Chinese Bentonite Suppliers for Paints

2.1 Ashapura China Clay Co.

- Supplies high-purity calcium bentonite for industrial paints and coatings.

- Export-oriented, serving markets in Europe, the Middle East, and North America.

2.2 Zhejiang Fenghong Clay Chemical Co.

- Focuses on bentonite-based rheology modifiers for water-based paints.

- Produces nano-grade bentonite for advanced coatings.

Why Chinese Bentonite is Popular in Paints?

Competitive pricing and large-scale production.

Specialized in processed calcium bentonite for paint formulations.

Growing investment in sustainable and eco-friendly coatings.

3. India: A Key Exporter of Paint-Grade Bentonite

India has large bentonite reserves in Gujarat, Rajasthan, and Tamil Nadu, making it a top supplier of bentonite for paints. Indian manufacturers focus on refined bentonite with excellent dispersion properties, ensuring smooth and stable paint formulations.

Key Indian Bentonite Suppliers for Paints

3.1 Ashapura Group

- One of the largest bentonite producers in India.

- Supplies high-performance bentonite for the coatings and construction industries.

- Exports to Asia, Africa, and Europe.

3.2 Kutch Minerals

- Produces white bentonite with low iron content, ideal for premium paints and coatings.

- Known for high-purity, fine-milled calcium bentonite.

Why Indian Bentonite is Used in Paints?

High-purity bentonite with excellent dispersion.

The strong supply chain for international exports.

Growing focus on processed and eco-friendly bentonite products.

4. Turkey: A Rising Star in Bentonite Production

Turkey has rich bentonite reserves, particularly in the Anatolia region. Turkish producers focus on high-quality, low-iron bentonite, making it suitable for high-end paints and industrial coatings.

Key Turkish Bentonite Suppliers for Paints

4.1 Canbensan Bentonite

- Specializes in high-purity calcium bentonite for industrial paints.

- Supplies European and Middle Eastern markets.

4.2 KarBen Bentonite

- Produces fine-milled bentonite for water-based and oil-based paints.

- Focuses on natural, eco-friendly additives for coatings.

Why Turkish Bentonite is Gaining Popularity?

Low-iron content, ideal for premium paints.

Well-established export network to Europe and the Middle East.

Growing investments in bentonite processing technology.

5. Iran: An Emerging Bentonite Supplier

Iran has significant bentonite reserves, particularly in Khorasan, Semnan, and Yazd provinces. The country’s refined bentonite is used in paints, ceramics, and industrial coatings.

Key Iranian Bentonite Suppliers for Paints

5.1 Iran Bentonite Co.

- Specializes in white and high-purity calcium bentonite.

- Supplies Asian and Middle Eastern markets.

5.2 Sepehr Mine Group

- Focuses on low-dust, fine-milled bentonite for paint applications.

- Exports to Turkey, India, and China.

Why Iranian Bentonite is in Demand?

Cost-effective and high-quality calcium bentonite.

Growing market presence in Asia and the Middle East.

Strategic location for global exports.

Future Trends in the Bentonite Market for Paints

1. Increasing Demand for Eco-Friendly Paints

- The shift toward low-VOC and water-based paints is driving demand for natural bentonite additives.

2. Technological Advancements in Bentonite Processing

- Nano-grade and high-purity bentonite will play a key role in advanced coatings.

3. Expansion of Global Bentonite Production

- Countries like Brazil, South Africa, and Russia are investing in bentonite mining and processing.

4. Rising Use of Bentonite in Smart Coatings

- Smart paints with self-cleaning and antimicrobial properties will use bentonite-based formulations.

Future Trends: Bentonite in Advanced Paint Technologies

The paint industry is evolving with new formulations and advanced coatings, where bentonite plays a crucial role.

1. Smart and Self-Cleaning Paints

- Bentonite-based coatings are being developed for self-cleaning and antimicrobial properties.

- Used in hospitals, schools, and public spaces to prevent bacteria growth.

2. High-Performance Nano-Coatings

- Bentonite is used in nano-paint formulations for ultra-thin protective coatings.

- Applied in automotive, aerospace, and high-tech industries.Bentonite for Painting

3. Eco-Friendly and Sustainable Paints

- Demand for biodegradable, toxin-free paints is increasing.

- Bentonite is being used as a natural alternative to synthetic additives.

4. Advanced UV-Resistant and Heat-Reflective Coatings

- Bentonite-based coatings help reduce heat absorption in buildings.

- Used in energy-efficient roofing and exterior wall paints.

Bentonite – A Game-Changer for the Paint Industry

Bentonite is a key ingredient in high-quality paints and coatings, offering superior stability, texture, and durability. Its ability to suspend pigments, prevent sagging, and enhance adhesion makes it an essential additive for water-based, oil-based, and industrial coatings.

As the paint industry moves toward sustainability and high-performance coatings, the demand for bentonite-based formulations is set to grow. With major producers worldwide supplying high-purity bentonite, this mineral will continue to play a crucial role in the future of painting and coatings.

https://iranmineral.net/minerals-in-industry/