Precision Weighting for High-Performance Drilling Fluids

Micronized barite for oilfield use is a refined, ultra-fine form of natural barite (baryte), chemically known as barium sulfate (BaSO₄). Engineered to meet the demanding conditions of modern drilling operations, micronized barite plays a critical role in well control, drilling fluid stability, and operational safety across onshore and offshore oilfields.

As drilling environments become deeper, hotter, and more complex, oilfield service companies increasingly rely on micronized barite to deliver consistent density, superior suspension, and enhanced rheological performance. According to the American Petroleum Institute (API), barite remains the most widely used weighting agent in drilling fluids worldwide (https://www.api.org).

What Is Micronized Barite for Oilfield Use?

Micronized barite is produced through advanced grinding, micronization, and air classification, resulting in particle sizes typically ranging from 1 to 10 microns. This fine particle distribution improves the performance of water-based, oil-based, and synthetic drilling fluids.

| Micronized barite for oilfield use is a refined, ultra-fine form of natural barite (baryte), chemically known as barium sulfate (BaSO₄).The oil and gas industry is the largest consumer of barite, accounting for the majority of global demand. |

Key Physical & Chemical Properties

-

Chemical Formula: BaSO₄

-

API Specific Gravity: 4.1–4.2+

-

Average Particle Size (D50): 1–5 microns

-

Solubility: Insoluble in water and drilling fluids

-

Chemical Reactivity: Inert

-

Thermal Stability: Excellent at high downhole temperatures

These properties are recognized by Encyclopaedia Britannica and oilfield materials references (https://www.britannica.com).

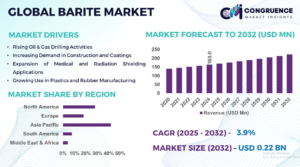

Global Barite Market Statistics: Oilfield Dominance

The oil and gas industry is the largest consumer of barite, accounting for the majority of global demand.

Market Data & Industry Insights

-

Global barite production exceeds 8 million metric tons annually

-

80–85% of barite consumption is used in oilfield drilling fluids

-

The global barite market is valued at approximately USD 1.5–2.0 billion

-

Demand for micronized and API-grade barite is growing at ~4% CAGR

These figures are supported by USGS, Statista, and Mordor Intelligence

(https://www.usgs.gov, https://www.statista.com, https://www.mordorintelligence.com).

“As drilling conditions become more challenging, micronized barite is increasingly used to enhance mud performance and wellbore stability,” — Oilfield Materials Analyst, Mordor Intelligence

Why Micronized Barite Is Preferred in Modern Oilfields

Traditional coarse barite can settle or sag under extreme conditions. Micronized barite addresses these challenges through improved physical behavior.

Enhanced Suspension & Reduced Sag

The ultra-fine particle size of micronized barite results in:

-

Better suspension in drilling fluids

-

Reduced barite sag in deviated and horizontal wells

-

More uniform density distribution

According to SPE (Society of Petroleum Engineers) publications, finer weighting materials significantly improve fluid stability in extended-reach wells (https://www.spe.org).

Improved Rheology & Well Control

Micronized barite contributes to:

-

Stable rheological properties

-

Precise hydrostatic pressure control

-

Reduced risk of kicks and blowouts

-

Enhanced cuttings transport

“Micronized barite allows better control of equivalent circulating density (ECD), especially in deepwater and HPHT wells,” — Drilling Fluids Engineer, offshore operations

Oilfield Applications of Micronized Barite

Water-Based Drilling Fluids (WBM)

In water-based mud systems, micronized barite improves:

-

Mud weight consistency

-

Suspension at low shear rates

-

Reduced solids settling

This makes it ideal for environmentally sensitive drilling operations, as highlighted by Oilfield Technology Magazine (https://www.oilfieldtechnology.com).

Oil-Based & Synthetic-Based Muds (OBM / SBM)

Micronized barite performs exceptionally well in oil-based systems due to:

-

Low oil absorption

-

Uniform dispersion

-

Improved thermal stability

These properties are critical for deepwater, high-angle, and HPHT drilling, as documented by Rigzone (https://www.rigzone.com).

Cementing & Well Completion Fluids

Beyond drilling, micronized barite is used in:

-

Weighted cement slurries

-

Completion and workover fluids

-

Plug and abandonment operations

Its fine particle size improves slurry homogeneity and reduces settling, according to Schlumberger oilfield cementing studies (https://www.slb.com).

Specialized Oilfield Terminology (SEO-Focused)

To align with oilfield professionals and technical buyers, key industry terms include:

-

API-Grade Barite: Barite meeting API 13A specifications

-

Weighting Agent: Material used to increase drilling fluid density

-

Barite Sag: Settling of weighting material under static conditions

-

Equivalent Circulating Density (ECD): Effective downhole pressure

-

HPHT Wells: High-pressure, high-temperature drilling environments

These keywords improve visibility for oilfield procurement and drilling engineering searches.

Quality Standards for Micronized Oilfield Barite

Oilfield barite must meet strict specifications, including:

-

Compliance with API 13A / ISO 13500

-

Specific gravity ≥ 4.1 or 4.2

-

Controlled particle size distribution

-

Low calcium, iron, and heavy metals

-

Consistent moisture content

API standards are outlined by the American Petroleum Institute

(https://www.api.org).

Environmental & Operational Advantages

Micronized barite offers several operational and environmental benefits:

-

Non-toxic and non-hazardous

-

Chemically inert in drilling fluids

-

Compatible with environmentally friendly mud systems

-

Reduces waste and reprocessing costs

“Using high-quality micronized barite helps reduce non-productive time and improves overall drilling efficiency,” — Drilling Operations Manager

Market Outlook: Future of Micronized Barite in Oilfields

Key growth drivers include:

-

Expansion of deepwater and offshore drilling

-

Increased drilling in HPHT reservoirs

-

Demand for high-performance drilling fluids

-

Technological advancements in mud engineering

Market forecasts from Mordor Intelligence indicate sustained demand for micronized oilfield barite through 2030

(https://www.mordorintelligence.com).

Conclusion: Micronized Barite as a Strategic Oilfield Material

Micronized barite has become an essential weighting agent for modern oilfield operations. Its superior suspension, precise density control, and compatibility with advanced drilling fluids make it a commercially and technically superior solution compared to conventional barite.

For oil and gas operators seeking safer drilling, improved well control, and optimized performance, micronized barite for oilfield applications remains a critical component of successful drilling programs.