The Science Behind the Shine

White cement is more than just a building material — it’s a symbol of purity, strength, and elegance. Known for its bright color and smooth texture, white cement is used in modern architecture, interior design, and decorative construction. But what truly sets it apart is its unique chemical composition, which gives it its signature whiteness and durability.

What Makes White Cement Different

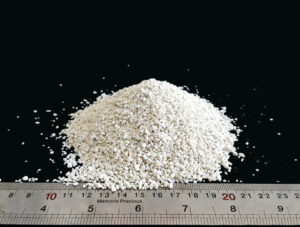

White cement is a type of Portland cement, but unlike grey cement, it’s made with raw materials low in iron, manganese, and other coloring oxides. Because of this, the result is a brilliant white powder that reflects light beautifully and enhances the appearance of any structure.

Moreover, while the production process is similar to grey cement, white cement requires high-purity limestone and kaolin clay instead of typical shale or iron-rich materials. This precise chemical balance ensures both strength and color consistency.

Key Chemical Components of White Cement

-

Calcium Oxide (CaO):

Makes up around 60–70% of white cement. It provides strength and helps in the hardening process. -

Silicon Dioxide (SiO₂):

Represents about 20–25%, contributing to the cement’s hardness and durability. -

Aluminum Oxide (Al₂O₃):

Accounts for 4–6%, improving the setting time and overall workability. -

Iron Oxide (Fe₂O₃):

Present in very small quantities (below 0.3%) to maintain the cement’s white color. Moreover, reducing iron oxide is the key to achieving brightness. -

Magnesium Oxide (MgO) and Sulfates:

These control setting time and prevent cracking, enhancing the cement’s long-term stability.

In addition, the low content of manganese and titanium compounds ensures the pure white tone that distinguishes white cement from all others.

Why the Chemical Composition Matters

-

Bright Color: Low iron and manganese ensure maximum whiteness.

-

High Strength: Rich in calcium and silica for superior bonding.

-

Smooth Finish: Fine particles deliver uniform texture and shine.

-

Eco-Friendly Production: Uses high-quality natural minerals with reduced emissions.

-

Durability: Balanced chemical makeup resists cracking and weathering.

Furthermore, this composition allows white cement to blend seamlessly with pigments, making it ideal for colored concretes, architectural facades, and artistic finishes.

Applications of White Cement

Because of its purity and chemical stability, white cement is perfect for:

-

Decorative wall finishes and sculptures.

-

Terrazzo and marble flooring.

-

Precast panels and monuments.

-

Modern architecture and luxury projects.

In addition, its reflective quality reduces heat absorption, keeping structures cooler — a valuable feature in hot climates.

The Perfect Blend of Science and Style

Finally, the chemical composition of white cement defines its beauty and performance. Whether you’re crafting elegant interiors, building striking exteriors, or creating artistic finishes, white cement offers the ideal balance of strength, color, and quality. Also, its unique formulation ensures long-lasting results that stand out for years.