Exploring the Different Types of Industrial Salt and Their Applications

Industrial salt is a critical component in various industries, from food processing to manufacturing and water treatment. Known for its purity and chemical properties, industrial salt comes in different forms, each tailored to specific applications. This article explores the different types of industrial salt and their unique uses. Different Types of Industrial Salt

What is Industrial Salt?

Industrial salt, primarily composed of sodium chloride (NaCl), is produced in large quantities for industrial purposes. Unlike table salt, which is used for consumption, industrial salt undergoes minimal processing and is tailored to meet the demands of different industries.

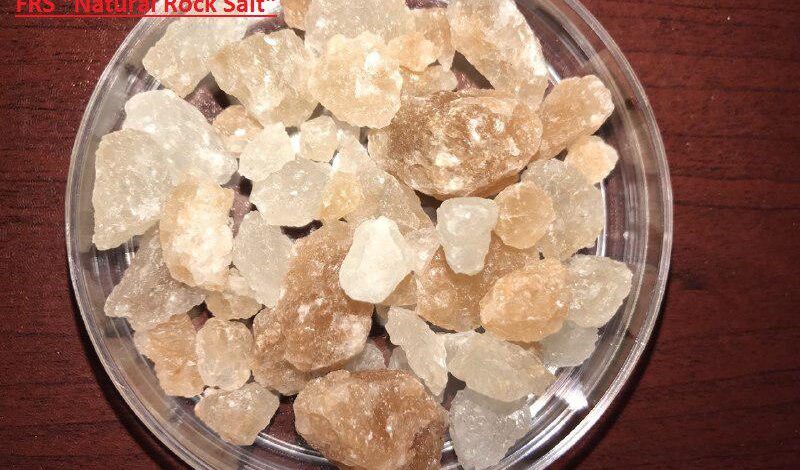

Rock Salt: The Heavy-Duty Mineral

Rock salt, also known as halite, is one of the most common forms of industrial salt. Mined from underground deposits, rock salt is characterized by its larger, coarser crystals and is typically less refined than other types of salt.

Applications in De-Icing and Road Safety

One of the primary uses of rock salt is in de-icing roads and walkways. Its coarse texture and ability to lower the freezing point of water make it an effective tool for preventing ice formation during winter.

Enhancing Road Safety

Rock salt is spread on roads and highways to melt snow and ice, ensuring safer driving conditions. Its affordability and effectiveness make it the go-to choice for municipalities and road maintenance crews.

Water Softening and Treatment

Rock salt is also used in water-softening systems to remove calcium and magnesium ions that cause water hardness.

Improving Water Quality

In water treatment plants, rock salt is used in ion exchange systems to soften water, enhancing the quality and extending the lifespan of pipes and appliances.

Solar Salt: The Natural Evaporate

Solar salt, also known as sea salt, is produced through the evaporation of seawater. It is known for its high purity and fine crystals, making it suitable for various industrial applications.

Food Processing and Preservation

Solar salt is widely used in the food industry for preserving and processing foods. Its natural production process and fine granules make it ideal for use in various culinary applications.

Maintaining Food Quality

In food processing, solar salt helps preserve the freshness and flavor of products, from cured meats to canned vegetables, ensuring that foods stay safe and tasty for consumers.

Chemical Manufacturing

In the chemical industry, solar salt is a key ingredient in the production of various chemicals, including chlorine and caustic soda.

Supporting Chemical Reactions

Solar salt is used in chemical manufacturing as a raw material, where its purity and consistency ensure reliable and efficient chemical reactions in the production of important industrial chemicals.

Vacuum Salt: The Ultra-Pure Option

Vacuum salt is produced through a controlled evaporation process in vacuum pans, resulting in a highly refined, pure salt form. Its consistent quality and fine texture make it ideal for industries requiring high-purity salt.

Pharmaceutical and Cosmetic Applications

Vacuum salt is widely used in the pharmaceutical and cosmetic industries, where purity is paramount. Its lack of impurities ensures that it meets the strict quality standards required in these fields.

Ensuring Product Safety

In pharmaceuticals, vacuum salt is used as a filler and to produce saline solutions. In cosmetics, it is used in products like bath salts and scrubs, where its purity guarantees safety and effectiveness for consumers.

High-Precision Manufacturing

Vacuum salt is also used in high-precision manufacturing processes, where the slightest impurity could affect the final product.

Iran Industrial Salt Manufacturers

Consistency in Production

Industries like electronics and glass manufacturing rely on vacuum salt for its consistent quality, which ensures uniformity and reliability in their products.