A High-Performance Mineral for Advanced Industrial Applications

Micronized barite powder is a premium, finely ground form of natural barite (baryte), chemically known as barium sulfate (BaSO₄). With ultra-fine particle sizes, exceptional chemical inertness, and high specific gravity, micronized barite has become a strategic material for industries requiring precision, performance, and consistency.

From chemical manufacturing and coatings to plastics, rubber, and radiation shielding, micronized barite powder delivers functional benefits that conventional fillers cannot achieve. According to industrial mineral experts, demand for micronized grades continues to rise as manufacturers seek higher-quality and more efficient formulations (https://www.azom.com).

What Is Micronized Barite Powder?

Micronized barite powder is produced by advanced grinding and classification processes that reduce natural barite to micron-level particle sizes, typically ranging from 1 to 10 microns. This ultra-fine structure enables superior dispersion, smoother surfaces, and enhanced functional performance in end-use applications.

| Micronized barite powder is a premium, finely ground form of natural barite (baryte), chemically known as barium sulfate (BaSO₄).The global demand for micronized mineral fillers has grown rapidly,In plastics and polymers, micronized barite functions as a high-density, non-toxic filler |

Key Characteristics of Micronized Barite

-

Chemical Formula: BaSO₄

-

Average Particle Size (D50): 1–5 microns

-

Specific Gravity: 4.3–4.6 g/cm³

-

Whiteness: High (depending on ore quality)

-

Oil Absorption: Low

-

Chemical Reactivity: Extremely low

These properties are well documented by Encyclopaedia Britannica and materials science references (https://www.britannica.com).

Global Market Statistics for Micronized Barite Powder

The global demand for micronized mineral fillers has grown rapidly due to performance-driven industries such as coatings, polymers, and specialty chemicals.

Market Size & Growth Trends

-

Global barite production exceeds 8 million metric tons per year

-

Micronized and value-added barite products represent 20–25% of industrial barite consumption

-

The micronized mineral fillers market is growing at a CAGR of ~4–5%

-

Asia-Pacific leads consumption due to strong growth in coatings, plastics, and chemical manufacturing

These insights are supported by reports from Statista and Mordor Intelligence

(https://www.statista.com, https://www.mordorintelligence.com).

“Micronized barite is increasingly preferred over conventional fillers because it enhances performance while maintaining chemical stability,” — Industrial Minerals Analyst, Research Nester (https://www.researchnester.com)

Why Micronized Barite Powder Is Preferred Over Standard Barite

The micronization process transforms barite from a basic mineral into a high-value functional material.

Enhanced Dispersion & Surface Finish

Ultra-fine particle size allows micronized barite to disperse evenly within liquids and polymers, resulting in:

-

Smoother coatings

-

Reduced sedimentation

-

Improved surface appearance

According to SpecialChem, micronized fillers significantly improve formulation homogeneity (https://www.specialchem.com).

Improved Chemical & Mechanical Performance

Micronized barite enhances:

-

Chemical resistance

-

Abrasion resistance

-

Dimensional stability

-

Density control without toxicity

“The fine particle size of micronized barite improves both physical and chemical stability in demanding formulations,” — Senior Formulation Chemist

Industrial Applications of Micronized Barite Powder

Micronized Barite in Paints & Coatings

Micronized barite is widely used in industrial, marine, and protective coatings. Its benefits include:

-

Improved opacity and brightness

-

Increased film density

-

Enhanced corrosion resistance

Industry insights from PCI Magazine confirm its role in high-performance coatings

(https://www.pcimag.com).

Plastics & Polymer Compounding

In plastics and polymers, micronized barite functions as a high-density, non-toxic filler. It is used to:

-

Increase weight without affecting processability

-

Improve acoustic insulation

-

Enhance dimensional stability

Applications include automotive components, electrical housings, and consumer products, as reported by PlasticsToday (https://www.plasticstoday.com).

Rubber, Sealants & Adhesives

Micronized barite improves the performance of:

-

Industrial rubber products

-

Chemical-resistant sealants

-

High-durability adhesives

Its low oil absorption and fine particle size enhance processing efficiency, according to AZoM – Materials Science (https://www.azom.com).

Radiation Shielding & Medical Applications

Thanks to its high density and purity, micronized barite is used in:

-

Radiation-shielding concrete

-

Medical diagnostic environments

-

Nuclear facility construction

Barium sulfate’s radiation attenuation properties are widely documented in medical and engineering literature (https://www.ncbi.nlm.nih.gov).

Specialized Industry Terminology (SEO-Focused)

To support technical buyers and improve SEO visibility, key industry terms include:

-

Micronized Barite Powder: Ultra-fine barium sulfate filler

-

D50 Particle Size: Median particle diameter

-

High-Density Mineral Filler: Material used to increase product weight

-

Low Oil Absorption Filler: Improves resin efficiency

-

Chemical-Grade Barite: High-purity BaSO₄ for industrial use

These terms align with search behavior of formulation chemists, procurement managers, and industrial buyers.

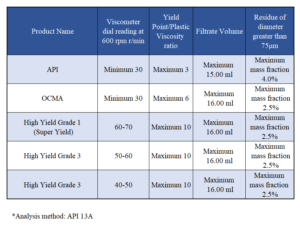

Quality Specifications for Micronized Barite Powder

High-quality micronized barite typically meets the following criteria:

-

BaSO₄ content: ≥ 95–98%

-

Particle size: Consistent micron-level distribution

-

Low iron and heavy metals

-

High whiteness index

-

Compliance with ISO, REACH, and regional standards

Regulatory guidance can be found through the European Chemicals Agency (ECHA)

(https://echa.europa.eu).

Sustainability & Environmental Advantages

Micronized barite is valued for its environmental stability:

-

Non-toxic

-

Non-flammable

-

Chemically inert

-

Long lifecycle performance

Responsible mining and processing support ESG and sustainability goals, as highlighted by the International Council on Mining & Metals (ICMM)

(https://www.icmm.com).

“Inert minerals like micronized barite offer long-term environmental safety in industrial applications,” — Environmental Materials Consultant

Market Outlook: Future of Micronized Barite Powder

Growth drivers include:

-

Rising demand for high-performance coatings

-

Expansion of advanced polymer technologies

-

Increased use of radiation-shielding materials

-

Shift toward non-toxic, inert mineral fillers

Market forecasts from Mordor Intelligence project steady growth for micronized barite applications

(https://www.mordorintelligence.com).

Conclusion: Micronized Barite Powder as a Value-Added Mineral Solution

Micronized barite powder represents the next generation of barite products, offering superior performance, consistency, and versatility. Its ultra-fine particle size, chemical inertness, and high density make it an indispensable material across coatings, plastics, rubber, chemical, and medical industries.

For manufacturers seeking reliable, high-performance, and compliant mineral fillers, micronized barite powder remains a commercially strategic choice.