Introduction to Barite in the Paper Industry

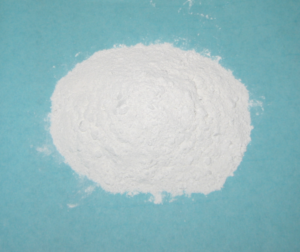

Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), is widely recognized for its unique properties that make it an invaluable additive in various industrial applications, including paper production. As the demand for high-quality paper products continues to rise, understanding the role of barite in enhancing paper quality and performance is crucial for manufacturers. This article explores the benefits of using barite in paper production, its applications, and its impact on the industry.

Benefits of Barite in Paper Production

1. Improved Opacity and Brightness

One of the primary advantages of incorporating barite into paper formulations is its ability to enhance opacity and brightness. Barite’s high refractive index allows it to scatter light effectively, resulting in paper that is more vibrant and visually appealing. This characteristic is particularly beneficial for high-quality printing papers, where color accuracy and brightness are essential. By using barite, manufacturers can achieve a more uniform and consistent finish, ensuring that the final product meets the highest aesthetic standards.

2. Enhanced Printability

Barite also plays a significant role in improving the printability of paper products. The mineral acts as a filler, providing a smooth surface that enhances ink adhesion and distribution. This is crucial for achieving sharp, clear images and text in printed materials. Papers that incorporate barite exhibit better ink absorption and reduced bleeding, resulting in high-quality prints that meet the expectations of consumers and businesses alike.

https://iranmineral.net/barite-manufacturers/

3. Cost-Effectiveness

In addition to its performance benefits, barite is a cost-effective solution for paper manufacturers. Its abundance and relatively low cost make it an attractive option for companies looking to optimize their production processes without sacrificing quality. By incorporating barite into their formulations, manufacturers can reduce the overall cost of production while maintaining the desired properties of the final product.

Applications of Barite in Paper Production

1. Coated Papers

Barite is commonly used in the production of coated papers, which are designed for high-quality printing applications. The mineral is added to the coating formulations to improve opacity, brightness, and smoothness. Coated papers that contain barite are ideal for magazines, brochures, and other printed materials that require vibrant colors and sharp images. The use of barite in these applications ensures that the final product meets the high standards expected by consumers.

2. Specialty Papers

In specialty paper applications, such as those used for labels, packaging, and art papers, barite plays a crucial role in achieving specific performance characteristics. Its unique properties allow manufacturers to tailor paper formulations to meet the stringent requirements of these industries. Whether it’s improving durability, enhancing print quality, or providing a specific finish, barite is an essential component in creating high-quality specialty papers.

3. Recycled Papers

As sustainability becomes a key focus in the paper industry, the use of barite in recycled paper production is gaining traction. Barite can help improve the quality of recycled fibers, enhancing their brightness and opacity. By incorporating barite into recycled paper formulations, manufacturers can produce high-quality products that meet consumer demands for environmentally friendly options without compromising on performance.

The Future of Barite in Paper Production

As the paper industry continues to evolve, the importance of barite as a key additive will only grow. With increasing consumer demand for high-quality, durable, and environmentally friendly paper products, manufacturers who leverage the unique properties of barite will be better positioned to meet these challenges.

1. Innovations in Barite Processing

Recent advancements in barite processing techniques have led to the development of higher purity grades and finer particle sizes. These innovations allow manufacturers to create papers with improved performance characteristics, such as enhanced opacity and better printability. As processing technologies continue to improve, the versatility of barite in paper formulations will expand, opening new opportunities for manufacturers.

2. Growing Demand for Eco-Friendly Products

The increasing emphasis on sustainability in the paper industry is driving the demand for eco-friendly products. Barite, being a naturally occurring mineral with low environmental impact, aligns well with this trend. Manufacturers who prioritize the use of barite in their formulations can appeal to environmentally conscious consumers and differentiate their products in a competitive market.

3. Expanding Applications of Barite

As research continues to uncover new applications for barite in the paper industry, manufacturers can explore innovative ways to incorporate this mineral into their formulations. From enhancing the performance of traditional papers to developing new specialty products, the potential for barite in paper production is vast.