Introduction to Bentonite in the Detergent Industry

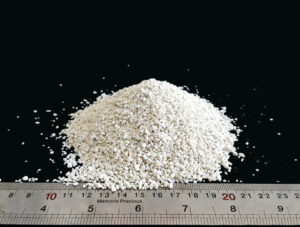

Bentonite, a naturally occurring clay mineral primarily composed of montmorillonite, has gained significant attention in various industrial applications, particularly in detergent manufacturing. Known for its unique properties, including high absorbency, swelling capacity, and ion exchange capabilities, bentonite serves as a vital ingredient that enhances the performance and effectiveness of detergents. As the demand for high-quality cleaning products continues to rise, understanding the role of bentonite in detergent formulations is crucial for manufacturers aiming to meet consumer expectations and industry standards.

Benefits of Using Bentonite in Detergent Manufacturing

1. Enhanced Cleaning Power

One of the primary advantages of incorporating bentonite into detergent formulations is its ability to enhance cleaning power. Bentonite’s unique structure allows it to effectively adsorb dirt, grease, and other impurities from surfaces. When used in laundry detergents, bentonite helps to lift and suspend soil particles, making it easier for the detergent to remove stains and dirt during the washing process. This results in cleaner, fresher fabrics and surfaces, meeting the high standards expected by consumers.

2. Improved Viscosity and Stability

Bentonite also plays a significant role in improving the viscosity and stability of detergent formulations. Its natural thickening properties allow manufacturers to create products with the desired consistency, ensuring that the detergent is easy to pour and apply. Additionally, bentonite helps stabilize liquid detergents, preventing separation and maintaining uniformity throughout the product’s shelf life. This stability is crucial for consumer satisfaction, as it ensures that the detergent performs consistently with each use.

3. Eco-Friendly and Sustainable Solution

As sustainability becomes a key focus in the detergent industry, bentonite offers an eco-friendly alternative to synthetic additives. Being a naturally occurring mineral, bentonite is biodegradable and non-toxic, making it a safe choice for consumers and the environment. Manufacturers who prioritize using bentonite in their formulations can appeal to environmentally conscious consumers and differentiate their products in a competitive market. By incorporating bentonite, companies can create effective cleaning solutions that align with the growing demand for sustainable products.

Applications of Bentonite in Detergent Formulations

1. Laundry Detergents

Bentonite is widely used in laundry detergents, where its absorbent properties help to enhance cleaning performance. Manufacturers can improve stain removal and overall cleaning efficacy by incorporating bentonite into powder or liquid laundry detergents. The mineral’s ability to suspend soil particles in water ensures that dirt is effectively washed away, resulting in cleaner clothes and fabrics. Additionally, bentonite can help reduce the amount of surfactants needed in formulations, contributing to a more sustainable product.

2. Dishwashing Detergents

In dishwashing detergents, bentonite serves a similar purpose by enhancing cleaning power and improving product stability. Its ability to adsorb grease and food residues makes it an effective ingredient in both manual and automatic dishwashing formulations. Bentonite helps to prevent the redeposition of soil on dishes, ensuring that they come out sparkling clean after each wash. Furthermore, its thickening properties contribute to the overall texture and usability of the product.

https://iranmineral.net/benefits-of-a-bentonite-hair-mask/

3. Industrial Cleaning Products

Bentonite is also utilized in industrial cleaning products, where its high absorbency and cleaning capabilities are particularly valuable. In formulations designed for heavy-duty cleaning applications, bentonite can help remove tough stains, grease, and grime from various surfaces. Its effectiveness in suspending soil particles makes it an ideal choice for industrial detergents used in manufacturing, automotive, and other sectors that require robust cleaning solutions.

The Future of Bentonite in Detergent Manufacturing

As the detergent industry continues to evolve, the importance of bentonite as a key ingredient will only grow. With increasing consumer demand for high-quality, eco-friendly cleaning products, manufacturers who leverage the unique properties of bentonite will be better positioned to meet these challenges.

1. Innovations in Bentonite Processing

Recent advancements in bentonite processing techniques have led to the development of higher purity grades and specialized formulations. These innovations allow manufacturers to create detergents with improved performance characteristics, such as enhanced cleaning power and better stability. As processing technologies continue to improve, the versatility of bentonite in detergent formulations will expand, opening new opportunities for manufacturers.

2. Growing Demand for Sustainable Products

The increasing emphasis on sustainability in the detergent industry is driving the demand for eco-friendly products. Bentonite, being a naturally occurring mineral with low environmental impact, aligns well with this trend. Manufacturers who prioritize using bentonite in their formulations can appeal to environmentally conscious consumers and differentiate their products in a competitive market.

3. Expanding Applications of Bentonite

As research continues to uncover new applications for bentonite in the detergent industry, manufacturers can explore innovative ways to incorporate this mineral into their formulations. From enhancing the performance of traditional detergents to developing new specialty cleaning products, the potential for bentonite in detergent manufacturing is vast.