An Overview of the Market

H1: Understanding Bentonite Import to India

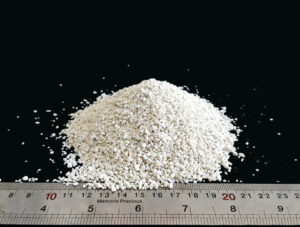

Bentonite, a versatile clay mineral known for its unique properties, has found significant applications across various industries in India. This natural resource is primarily used in drilling, construction, ceramics, and as a binding agent in several manufacturing processes. As India’s industrial sector continues to grow, the demand for bentonite is rising, making it essential to understand the dynamics of bentonite imports into the country.

The Growing Demand for Bentonite in India

India’s expanding industrial landscape is driving the increasing need for bentonite. Here are some key sectors relying on this valuable mineral:

- Oil and Gas Industry: Bentonite is a critical component in drilling fluids, where it acts as a mud weight and viscosity control agent. As India seeks to boost its energy production, the demand for bentonite in the oil and gas sector is on the rise.

- Construction Industry: Bentonite is used in the construction sector for various applications, including foundation drilling, soil stabilization, and as a sealant in landfills. The ongoing infrastructure development projects across India further contribute to the growing demand for this clay mineral.

- Ceramics and Glass Manufacturing: In the ceramics industry, bentonite is used as a binder and filler in the production of tiles, pottery, and glass. As the demand for ceramic products increases, so does the need for high-quality bentonite.

Key Bentonite Suppliers to India

India imports bentonite from several key producing countries known for their quality and reliability:

- United States: The U.S. is one of the largest producers of bentonite and supplies a significant portion of India’s imports. American bentonite is highly regarded for its quality, making it a preferred choice for many Indian manufacturers.

- Turkey: Turkey has emerged as a competitive supplier of bentonite, offering a variety of grades suitable for different applications. Turkish bentonite is increasingly recognized in the Indian market for its cost-effectiveness and quality.

- Greece: Greece is another important supplier of bentonite to India. The country’s high-quality deposits are well-suited for industrial applications, making Greek bentonite a valuable resource for Indian manufacturers.

Challenges in the Bentonite Import Market

While the bentonite import market in India shows promise, several challenges must be addressed:

- Regulatory Compliance: Import regulations and tariffs can impact the cost and availability of bentonite in India. Importers must navigate the regulatory landscape to ensure compliance and avoid delays in the import process.

- Quality Assurance: Ensuring the quality of imported bentonite is crucial for Indian manufacturers. Importers need to establish robust quality control measures to verify that the bentonite meets industry standards and specifications.

- Logistical Issues: The transportation of bentonite can pose logistical challenges due to its bulk and weight. Importers must optimize their supply chain and distribution networks to ensure timely delivery while minimizing costs.

ran mineral exporters to India

Future Outlook for Bentonite Imports to India

The future of bentonite imports to India appears bright, driven by the country’s ongoing industrial growth and the increasing demand for high-quality raw materials. As industries like oil and gas, construction, and ceramics continue to expand, the demand for bentonite is expected to rise, creating opportunities for both domestic and international suppliers.

Moreover, advancements in technology and product development may enhance the applications of bentonite, further boosting its demand in the Indian market. By addressing challenges such as regulatory compliance and quality assurance, stakeholders can position themselves to capitalize on the growing opportunities in the bentonite import sector.