API13 Section 10, (non-treated bentonite)

API 13 A (Non-treated Bentonite) Section 10 standards. It includes Sodium and contains at least 90% montmorillonite. The mineral is purely natural without any additives. The clay has a high swelling capacity around 25- 30 times the actual volume. It disperses easily when mixed with water and does not form lumps.

-

Advantage:

It is easy to mix and yields a homogeneous mineral slurry. It is compatible with cement and other construction additives, chemically stable, and tolerant of contaminants.

Non-treated bentonite d

- Soil condition:

Sand, rock, gravel, shale, clay, and cobble.

- Why choose API 13A section 10:

The use of untreated high-purity Wyoming sodium bentonite assists in the completion of trenching, soil mixing, drilled shafts, diaphragm and slurry walls, tunneling, and other hydraulic barrier applications.

-

Packaging:

Bulk, 4000 lb bulk bag, 3000 lb bulk bag, 2205 lb bulk bag, 2000 lb bulk bag, 100 lb bag, and 50 lb bag

- Bentonite for Construction

When it comes to construction drilling, the choice of materials plays a vital role in the success of your project. Using the right materials can significantly impact the efficiency, effectiveness, and overall outcome of your drilling operations. This is where AMICUS’ bentonite solutions shine.

- Construction Slurry Wall

AMICUS Chemical Solutions provides various materials to support the completion of slurry walls. Operating a clamshell or hydromill at any depth is an art, especially at depths of 80-200 feet below the surface. We are proud to assist in the construction of these incredible structures.

Bentonite performance minerals

7- Tunneling Construction Materials:

A single tunnel requires years of preparation and precise engineering. AMICUS provides a full line of products to support the construction of these incredible structures.

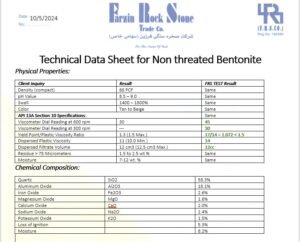

Chemical Features

| SiO2 | = 61.28 % |

|---|---|

| Al2O3 | = 17.79 % |

| Fe2O3 | = 3,01 % |

| CaO | = 4,54 % |

| Na2O | 2.70 % |

| MgO | = 2.10 % |

| K2O | = 1.24 % |

Physical Properties of our Bentonite API 13 A Section 10 :

| 600 d/d reading at Fan 35 viscometer | 30 min. |

|---|---|

| Amount of Filtration | 12,5 cc max. |

| Efficiency | 80 bbl. min. |

| Humidity | % 10 max. (percentage by weight) |

| Wet sieve analysis 200 Mesh (75 mic.) over sieve | % 2,5 max. (percentage by weight) |

| Yield point plastic viscosity ratio (Yp/Pv) | 1,5 max. |

| Disperse plastic viscosity (conditioned with 5 ml. Sodium hexametaphosphate into 350 ml of mixture at room temperature) | 10 cp min. |

| The ratio of Conditioned Yp/Pv to normal Yp/ Pv (Conditioning is carried out under the pressure of 200 psi, at 345O F for 16 hours under dynamic conditions and cooled at room temperature.) | 1,5 min. |

| The ratio of normal Yp / Pv to disperse Yp / Pv (Dispersions are measured in a mixture prepared with 3% H2O2) | 3 max. |

For Drilling Mud application :

- 1. Due to its high viscosity and gel-making properties, it provides retention of the agglomerates of the drilling slurry in suspension.

- 2. It ensures effective well cleaning by reducing slip speeds of cuts in the slurry.

- 3. It provides a stable and well-formed paste in the well wall and stabilizes the well with its high plastering property.

- 4. Due to its slippery property, it performs a very good lubricating function in the well, drill, and drilling line.