A Complete Guide

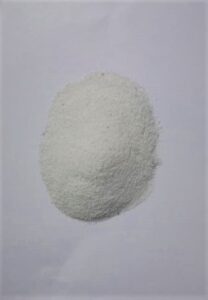

Barite, also known as barium sulfate (BaSO₄), is a versatile mineral with widespread applications in several industries. In the glasses and ceramic sector, it plays a vital role in improving brightness, density, and durability. Because of its purity and performance, the price per ton of barite for glasses and ceramic varies according to grade, processing, and global demand. For buyers, understanding these factors helps ensure the best quality at the right cost.

Why Barite Is Essential in Glasses and Ceramic

Barite has unique properties that make it valuable in glass and ceramic manufacturing. First, it enhances brightness and provides high whiteness, which improves the final product’s appearance. Second, it increases the density of glass, making it stronger and more durable. Moreover, in ceramics, barite contributes to smoothness, resistance, and a glossy finish.

Key benefits include:

-

Glasses industry – increases brilliance, improves strength, and boosts resistance to chemical corrosion

-

Ceramics industry – enhances smoothness, brightness, and firing stability

-

Eco-friendly advantage – barite is a naturally occurring mineral and safe for industrial use

As a result, barite remains a top choice for manufacturers who want quality and performance.

Factors That Affect Barite Price per Ton

The market value of barite depends on several elements. To begin with, purity and whiteness are crucial since high-purity barite commands premium pricing. In addition, processing type matters: raw barite is less expensive, while micronized or refined barite costs more because of extra treatment. Furthermore, origin and logistics influence costs, as importing from certain regions may increase expenses.

Another factor is global demand. When the glass and ceramic industries expand, prices naturally rise due to increased consumption. Therefore, buyers should evaluate both supply and demand before placing bulk orders.

Different Qualities of Barite for Glasses & Ceramic

1. Raw Barite

Raw barite is minimally processed and mainly used in bulk applications where moderate purity is acceptable.

Estimated Price per Ton: $90 – $150

2. Crushed or Ground Barite

This form is refined into specific particle sizes, making it suitable for ceramic glazes and general glass production.

Estimated Price per Ton: $150 – $250

3. Micronized Barite

Finely ground barite ensures smooth blending in glass and ceramics. It offers excellent whiteness and consistency, which are essential for premium products.

Estimated Price per Ton: $250 – $400

4. High-Purity Specialty Barite

This grade is designed for advanced glass and high-quality ceramic applications. Because of its superior brightness and controlled particle size, it is the most expensive form.

Estimated Price per Ton: $400 – $600

How to Choose the Right Grade for Your Business

Selecting the right barite requires careful consideration. First, companies should match the grade with the application—premium ceramics need high-purity micronized barite, while standard glass may work with ground grades. Second, evaluating budget and volume helps secure better deals through bulk purchasing. Finally, choosing a reliable supplier ensures consistent quality and uninterrupted production.

Commercial Benefits of Using Barite in Glasses & Ceramic

Investing in the right barite grade delivers clear commercial advantages. Manufacturers enjoy improved product quality, which increases customer satisfaction. They also benefit from cost efficiency, as high-performance barite reduces production waste. Furthermore, the steady global demand for glass and ceramics guarantees strong market stability.