Enhancing Quality, Brightness, and Durability

Introduction to Barite in Paint Manufacturing

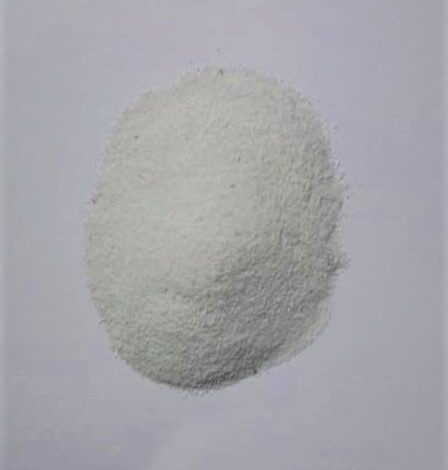

Barite (Barium Sulfate, BaSO₄) is a high-density mineral widely used in the paint and coating industry. Because of its brightness, chemical inertness, and fine particle size, it serves as an excellent filler and extender pigment in various paint formulations.

Moreover, barite improves paint gloss, smoothness, and resistance to corrosion, making it a preferred choice for industrial, automotive, and architectural coatings. As a result, manufacturers across the globe use barite to enhance both appearance and performance in high-quality paints.

Why Barite Is Essential for the Paint Industry

1. Exceptional Brightness and Opacity

Barite’s natural whiteness and high refractive index help improve the brightness and opacity of paint. Consequently, it increases light reflection, ensuring vibrant and long-lasting colors. Additionally, it helps reduce the consumption of expensive pigments, such as titanium dioxide, without compromising coverage.

2. Improved Durability and Smoothness

Because of its fine particle size and high density, barite enhances paint smoothness and surface finish. It provides a uniform texture, improves abrasion resistance, and increases film thickness stability. Therefore, paints containing barite maintain their finish longer, even under harsh weather conditions.

3. Chemical and Weather Resistance

Barite is chemically inert, meaning it does not react with binders, solvents, or other paint ingredients. As a result, it enhances paint stability and provides resistance against acids, alkalis, and moisture. This property makes barite particularly valuable for outdoor and marine coatings.

Applications of Barite in Different Paint Types

1. Industrial Coatings

In heavy-duty coatings, barite improves film strength, adhesion, and corrosion resistance. Furthermore, it acts as a protective layer on metal surfaces, extending product lifespan.

2. Decorative and Architectural Paints

Barite contributes to smooth application and consistent color distribution. Additionally, it improves anti-yellowing properties, ensuring that interior and exterior paints retain their original color for years.

3. Automotive Paints

In the automotive sector, barite helps create high-gloss, durable finishes. Its high density also improves scratch resistance, providing vehicles with superior surface protection.

Advantages of Using Barite in Paint Formulation

-

Enhances brightness and color quality

-

Reduces pigment cost without affecting coverage

-

Increases film durability and resistance

-

Improves viscosity control in formulations

-

Provides better weather and UV protection

Because of these benefits, barite has become a cost-effective and high-performance additive in modern paint manufacturing.

Choosing High-Quality Barite for Paint Production

Leading suppliers provide high-purity barite that meets ISO and ASTM quality standards. When selecting barite, manufacturers should focus on whiteness level, particle size distribution, and oil absorption rate. Reliable suppliers ensure consistent quality, competitive pricing, and timely global delivery, helping producers maintain efficiency and brand reputation.

Conclusion: The Role of Barite in Modern Paints

In conclusion, barite for the paint industry plays a vital role in improving paint brightness, strength, and protection. It is a versatile and cost-effective mineral that enhances the performance and durability of every coating.

Therefore, manufacturers seeking superior quality and long-term performance should choose high-purity barite from trusted suppliers. With the right material, businesses can achieve better color results, improved protection, and greater customer satisfaction.