Strength, Stability, and Quality

Introduction to Barite in Rubber and Plastic Manufacturing

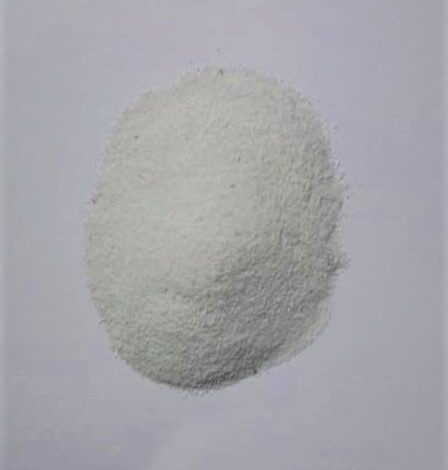

Barite (Barium Sulfate – BaSO₄) is a high-density, chemically inert mineral that plays a vital role in the rubber and plastic industries. Because of its excellent purity, brightness, and compatibility, barite serves as a cost-effective filler and performance enhancer in a wide range of products.

Moreover, manufacturers value barite for its ability to improve strength, thermal stability, and sound insulation, making it essential in automotive, construction, and consumer goods applications.

Why Use Barite in Rubber and Plastic?

Barite is not just a filler—it’s a performance-improving additive that enhances the physical, mechanical, and visual properties of materials.

1. Enhanced Strength and Durability

Adding barite to rubber and plastic significantly increases product density and hardness. Consequently, it improves impact resistance and helps finished products withstand mechanical stress and pressure.

2. Excellent Dispersion and Smooth Finish

Because of its fine particle size and smooth texture, barite disperses easily in polymers. Therefore, it creates uniform mixtures, improving surface quality, gloss, and smoothness in molded or extruded items.

3. Thermal and Sound Insulation

Barite’s high density also provides thermal and acoustic insulation. As a result, it is commonly used in automotive panels, soundproofing materials, and electrical components that require both strength and insulation.

Applications of Barite in Rubber and Plastic Industries

1. Automotive Manufacturing

In the automotive sector, barite improves the strength, weight balance, and vibration resistance of plastic components. Furthermore, it helps reduce noise levels and enhances stability in tires, hoses, and gaskets made with rubber compounds.

2. Construction Materials

Plastic and rubber materials containing barite are used in flooring, pipes, and insulation products. Because of its fire resistance and chemical stability, barite ensures long-lasting performance in demanding environments.

3. Consumer and Industrial Goods

Barite-based fillers are widely applied in appliances, packaging materials, and electrical casings. Additionally, its brightness enhances the visual appeal of white and colored plastics, improving final product aesthetics.

Advantages of Using Barite in Rubber and Plastic

-

Increases density and mechanical strength

-

Improves gloss, color stability, and texture

-

Provides excellent heat and sound insulation

-

Reduces production costs by replacing expensive resins

-

Enhances resistance to aging, chemicals, and wear

Therefore, barite serves both functional and economic benefits, helping manufacturers deliver high-quality, durable products at competitive costs.

Choosing High-Quality Barite for Rubber and Plastic

Selecting the right barite supplier is crucial for achieving consistent quality and production efficiency. Premium-grade barite should have high brightness, low oil absorption, uniform particle size, and minimal impurities.

Reputable suppliers comply with ISO and ASTM standards, offering customized particle sizes to match your specific manufacturing needs. Moreover, consistent supply ensures stable production and product uniformity across all applications.

Conclusion: Barite – The Ideal Filler for Performance and Profitability

In conclusion, barite for the rubber and plastic industry is more than a filler—it’s a value-adding mineral that enhances durability, performance, and visual quality. Its unique properties make it indispensable in automotive, construction, and consumer products.

Therefore, choosing high-purity barite from a trusted supplier guarantees long-term reliability, improved performance, and increased profitability for manufacturers worldwide.