Trusted Source for High-Quality Industrial Minerals

Introduction to Barite Mining Companies

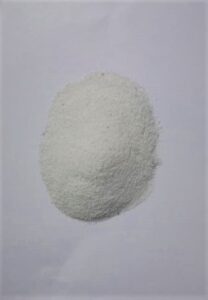

A barite mining company plays a vital role in supplying one of the most essential industrial minerals in the world — barite (barium sulfate, BaSO₄). Known for its high density, chemical stability, and purity, barite is widely used in oil and gas drilling, paint, plastic, rubber, and chemical industries.

Because of the growing demand for energy and industrial materials, reliable barite mining companies focus on efficient extraction, advanced processing, and global distribution. As a result, they help meet the needs of international markets with consistent quality and performance.

Why Choose a Professional Barite Mining Company

1. Reliable Resource Management

A professional barite mining company operates high-quality deposits with modern technology to ensure steady production. By maintaining sustainable mining practices, these companies maximize mineral recovery while minimizing environmental impact. Therefore, clients receive a continuous supply of premium-grade barite for long-term projects.

2. Advanced Processing and Quality Control

Top mining companies use state-of-the-art grinding, flotation, and purification systems to achieve high-purity barite (BaSO₄ above 95%). Furthermore, strict laboratory testing and certification ensure the final product meets international standards, including API 13A specifications required for drilling applications.

3. Global Export and Logistics Expertise

Leading barite mining companies not only mine and process the mineral but also handle efficient packaging, storage, and export logistics. With access to strategic ports and shipping routes, they deliver products to clients across Asia, Europe, Africa, and the Americas. Consequently, they provide fast, cost-effective, and reliable international trade solutions.

Applications of Barite from Mining Companies

1. Oil and Gas Drilling

In the energy industry, barite serves as a weighting agent in drilling fluids, maintaining pressure control and preventing blowouts. Because of its high specific gravity (4.1–4.3) and chemical inertness, barite ensures safe and efficient drilling operations under extreme conditions.

2. Paint, Plastic, and Rubber Manufacturing

Barite improves whiteness, smoothness, and durability in paints and coatings. Additionally, it enhances strength and resistance in rubber and plastic compounds. Therefore, manufacturers rely on barite to achieve premium product performance and longevity.

3. Chemical and Glass Industries

High-purity barite is a key ingredient in producing barium-based chemicals and specialized glass. It increases density and transparency, making it valuable for laboratory glassware, electronics, and optical materials.

Benefits of Partnering with a Leading Barite Mining Company

Working with a reputable barite mining company ensures:

-

Consistent product quality with strict QC testing

-

Flexible supply options for bulk or customized needs

-

Competitive pricing through efficient production

-

Technical support for various industrial applications

-

Reliable global delivery through advanced logistics

Moreover, these companies maintain sustainable practices to protect the environment while supporting economic development in mining regions.

Conclusion: Your Reliable Partner in Barite Supply

In conclusion, a barite mining company provides far more than raw materials — it delivers innovation, reliability, and quality. Through advanced mining technology, strict standards, and strong export capabilities, these companies have become key players in global industrial supply chains.

Therefore, whether you operate in oil and gas, manufacturing, or chemical production, choosing a trusted barite mining company ensures steady supply, cost efficiency, and superior performance. With commitment and expertise, these companies continue to shape the future of the global barite market.