The Key to Stronger and Cleaner Metal Castings

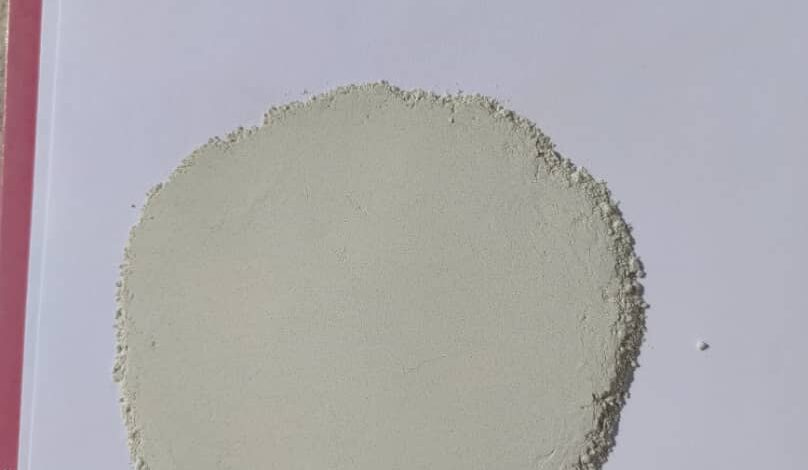

What Is Bentonite Clay for Foundry Use?

Bentonite is a natural clay mineral composed mainly of montmorillonite, known for its binding strength, thermal stability, and moisture retention. In the foundry industry, bentonite plays a vital role in sand molding systems used for casting iron, steel, and non-ferrous metals.

When mixed with foundry sand and water, bentonite forms a cohesive mold with excellent plasticity and strength. This ensures that molten metal holds its shape during pouring and cooling, resulting in precise, smooth, and defect-free castings.

How Bentonite Enhances Foundry Operations

1. Excellent Binding Properties

Bentonite binds sand grains firmly together, creating a durable and flexible mold. Its natural bonding ability helps withstand the mechanical stress of metal pouring and cooling, preventing cracks and deformation.

2. Superior Thermal Stability

Foundry molds face extreme temperatures during casting. Bentonite clay maintains its strength under heat, ensuring dimensional accuracy and smooth surface finishes for all metal types.

3. Controlled Permeability

Bentonite-based molding sand provides balanced permeability — it allows gases to escape during metal pouring while maintaining the mold’s integrity. This helps prevent blowholes, porosity, and surface defects in cast parts.

4. Easy Reusability and Reconditioning

After casting, the sand-bentonite mixture can be reconditioned and reused multiple times. This reduces material waste and production costs, making bentonite an economical and sustainable choice for foundries.

Key Benefits of Using Bentonite in Foundries

High Strength and Plasticity

Bentonite delivers consistent mold strength and plasticity, allowing foundries to produce complex and detailed casting shapes with minimal defects.

Uniform Mold Quality

Its fine particles distribute evenly through the sand mixture, creating a uniform texture that improves casting precision and repeatability.

Environmentally Friendly Material

Bentonite is a natural and non-toxic clay, safe for workers and compliant with environmental regulations. It supports eco-conscious foundry practices without compromising performance.

Cost Efficiency

Because bentonite can be regenerated and reused, it significantly lowers production costs and maximizes resource efficiency.

Why Choose Our Foundry-Grade Bentonite?

We provide premium-grade sodium bentonite specifically engineered for foundry applications. Our product offers high thermal durability, excellent green and dry strength, and superior bonding properties.

Whether you produce gray iron, ductile iron, steel, or non-ferrous castings, our bentonite ensures consistent mold performance and outstanding casting results. We offer bulk supply options, quality assurance, and competitive pricing for foundries of all sizes.

Contact Us Today

Enhance your casting performance with top-quality bentonite for foundry applications.

Get in touch today for technical specifications, samples, or bulk pricing.