Gilsonite, a naturally occurring hydrocarbon resin, is becoming increasingly vital in the chemical industry.

Known for its unique properties, such as high carbon content and excellent solubility in organic solvents, Gilsonite enhances the performance of various chemical formulations. This article explores the diverse applications of Gilsonite in the chemical industry, highlighting its benefits and significance.

What is Gilsonite?

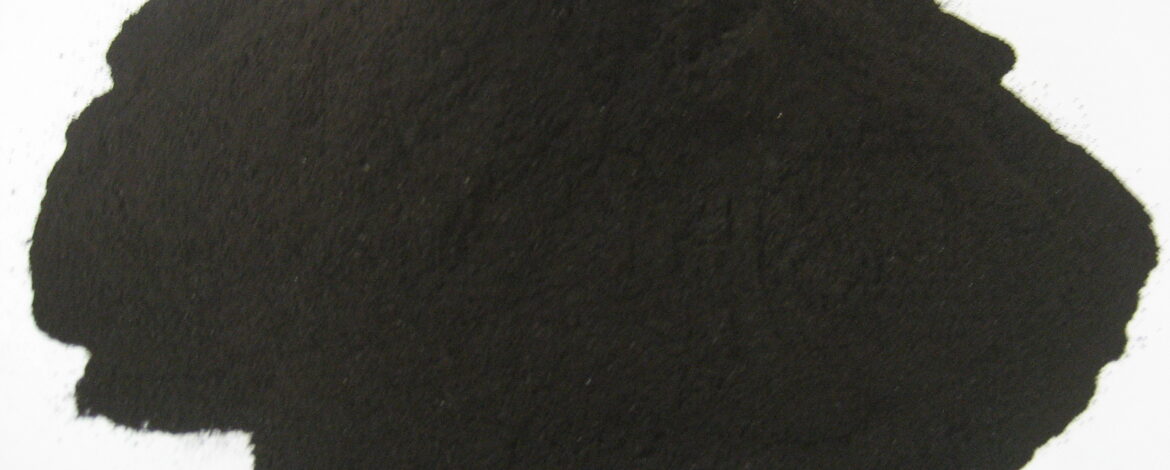

Gilsonite is a type of natural asphaltite derived from the Gilsonite mine in Utah. It is characterized by its dark color, brittle texture, and high melting point. Due to its unique composition, Gilsonite dissolves readily in organic solvents, making it an effective additive in various chemical products. Its versatility allows it to be used in numerous applications, from coatings to adhesives and beyond.

Benefits of Gilsonite in the Chemical Industry

1. High Carbon Content

One of the primary advantages of using Gilsonite in chemical formulations is its high carbon content. This property enhances the thermal stability and performance of products such as coatings and inks. Gilsonite’s carbon-rich composition improves the resistance to heat and UV radiation, ensuring that the final products maintain their quality over time.

2. Excellent Solubility

Gilsonite’s excellent solubility in organic solvents makes it an ideal additive for various chemical applications. It readily blends with resins, oils, and other components, enhancing the overall performance of formulations. This solubility is particularly beneficial in producing paints, varnishes, and sealants, where uniform distribution of ingredients is crucial for product quality.

https://iranmineral.net/gilsonite-usage-…-fluid-additives/

3. Improved Adhesion and Durability

In the chemical industry, Gilsonite is known for improving adhesion and durability in various formulations. When used in coatings and adhesives, it enhances the bonding strength between surfaces, ensuring long-lasting performance. This is particularly important in industries such as construction, automotive, and manufacturing, where high-quality adhesion is essential for product longevity.

Applications of Gilsonite in the Chemical Industry

1. Coatings and Paints

Gilsonite is widely used in the formulation of coatings and paints. Its ability to improve color stability, gloss, and resistance to fading makes it an invaluable ingredient. By incorporating Gilsonite, manufacturers can produce high-performance coatings that withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

2. Inks and Printing

In the printing industry, Gilsonite serves as a pigment extender and binder. Its unique properties enhance the flow and dispersion of pigments, resulting in vibrant and consistent ink formulations. The addition of Gilsonite improves the overall quality of inks, making them more durable and resistant to smudging and fading, which is crucial for high-quality printed materials.

3. Adhesives and Sealants

Gilsonite is an effective additive in adhesives and sealants, improving their performance and reliability. Its properties enhance the bonding strength and flexibility of formulations, making them suitable for a wide range of applications, from construction to automotive. By using Gilsonite in adhesives, manufacturers can create products that withstand stress and environmental factors, ensuring long-lasting adhesion.

Iran mineral company