The Key to Superior Industrial Performance

Introduction to High Purity Barite

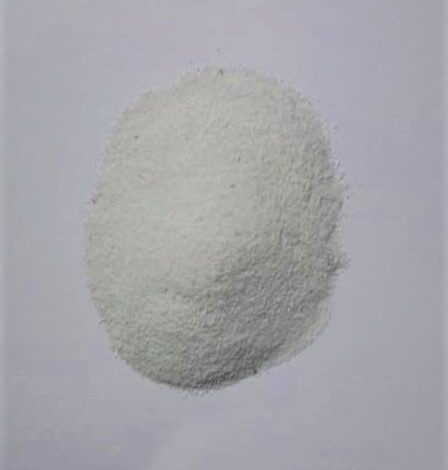

High Purity Barite is a premium-grade mineral composed primarily of barium sulfate (BaSO₄). Because of its exceptional density, brightness, and chemical stability, it is a vital material used in oil and gas drilling, paints, plastics, and chemical industries.

Furthermore, industries that require consistent quality and reliable performance choose high purity barite for its proven stability and purity. Its high specific gravity and inert chemical nature make it ideal for demanding industrial applications.

What Makes High Purity Barite Different?

Unlike standard barite, high purity barite undergoes advanced processing to remove impurities such as silica, iron, and other minerals. This purification process ensures a product that delivers superior brightness, higher density, and better performance in all applications.

1. Exceptional Purity and Density

High purity barite typically contains more than 95% barium sulfate, ensuring consistent results. As a result, it performs better as a weighting agent in drilling fluids and provides optimal coverage in paints and coatings.

2. Chemical Inertness

Since it is chemically stable, high purity barite does not react with acids, alkalis, or other additives. Therefore, it guarantees durability and long-term performance in industrial formulations.

3. Fine Particle Size

Manufacturers process high purity barite into fine, uniform particles. Consequently, it blends easily into liquids and solids, creating smooth textures and improved dispersion.

Industrial Applications of High Purity Barite

Thanks to its unique physical and chemical properties, high purity barite serves multiple industries effectively.

1. Oil and Gas Industry

In drilling fluids, high purity barite acts as a primary weighting agent. It helps control pressure, prevents blowouts, and stabilizes wellbores. Moreover, its high specific gravity provides efficient mud weight without harming drilling performance.

2. Paints and Coatings

Barite enhances brightness, opacity, and smoothness in paint formulations. Additionally, it improves durability and corrosion resistance, ensuring long-lasting finishes in architectural and industrial coatings.

3. Plastics and Rubber

In the plastics and rubber industries, high purity barite increases density, soundproofing, and resistance to wear. Therefore, it strengthens final products while maintaining flexibility.

4. Chemical and Medical Applications

Purity barite is also used to produce barium-based chemicals and radiographic contrast agents. Because of its inert nature, it remains safe for specialized applications.

Commercial Quality and Supply Standards

Reliable suppliers of high barite follow API 13A and ISO standards to guarantee consistency. Moreover, leading manufacturers provide comprehensive quality reports, including chemical composition, moisture content, and particle size analysis.

When purchasing, customers should consider origin, processing quality, and certification. A trusted supplier ensures competitive pricing, timely delivery, and consistent performance in every shipment.

Conclusion: Choose High Barite for Reliability and Performance

In conclusion, high barite stands out as a versatile, high-quality mineral that meets the strictest industrial standards. Its chemical stability, high density, and brightness make it ideal for oil drilling, paints, plastics, and chemical manufacturing.

Therefore, businesses seeking premium-grade performance should invest in high barite from certified suppliers. With the right material, companies can achieve better efficiency, reliability, and long-term value in their production processes.