Key Supplier Insights for the Oil and Gas Industry

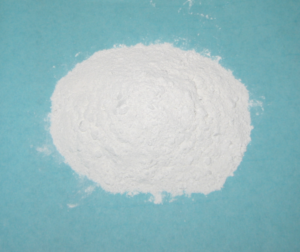

Barite is a critical mineral in the oil and gas industry, particularly in oil well drilling. Its high density is essential for maintaining pressure control and ensuring efficient drilling operations. For companies involved in the sector, understanding the role of oil well drilling barite and sourcing reliable suppliers is crucial for smooth, cost-effective operations. This guide explores the importance of barite in drilling and provides tips on finding dependable suppliers.

Why is Barite Important in Oil Well Drilling?

Barite (barium sulfate) is a naturally occurring mineral with a high density, making it ideal for oil well drilling. Its key advantages include:

-

Pressure Control: Barite is a primary component in drilling fluids (muds) that balance the pressure between the wellbore and surrounding formation. Consequently, it prevents blowouts and maintains safe drilling conditions.

-

Lubrication: Drilling fluids containing barite reduce friction between the drill bit and the wellbore. Therefore, operations are smoother, and equipment lifespan is extended.

-

Cost-Effectiveness: Compared to alternative materials, barite is relatively affordable while providing necessary performance for safe and efficient drilling.

-

Environmental Considerations: As an inert material, barite is non-toxic and poses minimal environmental risks when properly handled, making it a preferred choice globally.

How to Find Reliable Oil Well Drilling Barite Suppliers

Sourcing barite requires selecting a supplier who provides consistent, high-quality products. The following steps can help ensure you partner with the right suppliers:

1. Research and Assess Supplier Reputation

Begin by researching suppliers and evaluating their industry reputation. Look for established companies with a proven track record of delivering high-quality barite consistently. Additionally, check reviews, ratings, and testimonials from other oil and gas firms, as these provide insights into reliability and performance.

2. Verify Quality and Compliance Standards

Barite for oil well drilling must meet specific quality and regulatory standards. Therefore, choose suppliers who can provide certifications, such as API (American Petroleum Institute) compliance documents. Furthermore, request product samples to test quality before placing large orders, ensuring the material meets your operational requirements.

3. Check for Competitive Pricing and Bulk Discounts

Pricing is crucial, especially when buying in large volumes. Compare multiple suppliers to find competitive deals and inquire about bulk discounts or tiered pricing. By doing so, you can maximize cost savings without sacrificing quality.

4. Ensure Timely Delivery and Logistics Support

Project timelines in oil and gas are often tight. Consequently, selecting a supplier with reliable delivery and logistics support is vital. Review their lead times and delivery history to confirm they can meet deadlines. Moreover, a capable logistics partner ensures the barite arrives in optimal condition.

5. Focus on Long-Term Partnerships

Finally, building long-term relationships with suppliers enhances operational efficiency. A dependable supplier supports both immediate needs and future projects, offering consistent quality, transparency, and strong communication. This fosters trust and reduces risks associated with supply chain disruptions.