Bentonite’s Role in Oil-Based Detergents

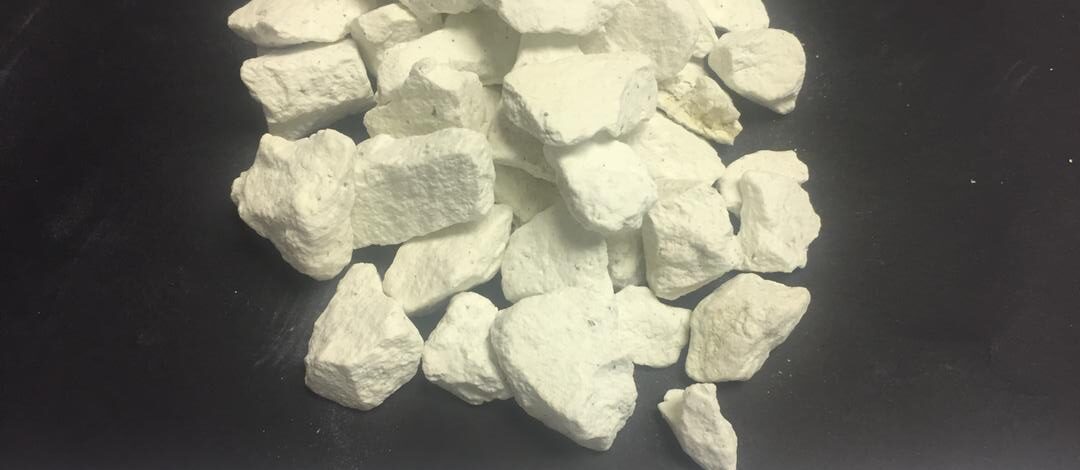

Bentonite is a versatile mineral widely used in various industrial applications, including oil-based detergents. Due to its absorbent, thickening, and suspension properties, bentonite plays a crucial role in formulating high-performance detergents used in cleaning, degreasing, and emulsifying oily substances.

With the growing demand for industrial and household cleaning products, the global market for bentonite-based oil detergents is expanding. This article explores the leading global producers of bentonite for oil detergents, their major production regions, and future industry trends.

1. The Importance of Bentonite in Oil Detergents

Bentonite is used in oil detergent formulations for its ability to:

- Absorb grease and oil residues effectively.

- Act as a suspending agent to prevent separation in liquid detergents.

- Enhance detergent viscosity and stability.

- Improve cleaning efficiency in industrial degreasers and household detergents.

The two main types of bentonite used in detergents are:

- Sodium Bentonite – Provides high swelling capacity and excellent absorption properties.

- Calcium Bentonite – Used as a mild abrasive and thickening agent.

With these properties, bentonite-based detergents are widely used in automotive, industrial, and household cleaning applications.

2. United States: The Largest Producer of High-Quality Bentonite

The United States is the world’s largest producer of sodium bentonite, primarily sourced from Wyoming, Montana, and Texas. U.S. bentonite is known for its high absorption capacity and superior suspension properties, making it ideal for oil-based detergent production.

Key U.S. Bentonite Suppliers for Oil Detergents

2.1 AMCOL International (Minerals Technologies Inc.)

- One of the largest global suppliers of bentonite for detergent applications.

- Produces high-purity sodium bentonite for enhanced cleaning performance.

- Exports to Europe, Asia, and the Middle East.

2.2 Wyo-Ben Inc.

- Specializes in low-dust, high-viscosity bentonite for detergent formulations.

- Focuses on custom bentonite blends for industrial and household detergents.

2.3 Black Hills Bentonite

- Supplies high-performance bentonite for cleaning and degreasing applications.

- Focuses on eco-friendly bentonite products for sustainable detergent production.

Why U.S. Bentonite is Preferred for Oil Detergents?

High-quality sodium bentonite with superior suspension properties.

Well-established supply chain for global exports.

Advanced processing techniques for improved performance in detergents.

3. China: A Major Exporter of Bentonite for Detergents

China is one of the largest producers of bentonite, supplying Asia, Europe, and the Middle East. Chinese bentonite is valued for its affordability and refined processing techniques, making it widely used in detergent manufacturing.

Key Chinese Bentonite Suppliers for Oil Detergents

3.1 Weifang Huawei Bentonite Group

- Produces high-purity bentonite for detergent applications.

- Exports to Southeast Asia and the Middle East.

3.2 Zhejiang Fenghong Clay Chemical Co.

- Specializes in fine-milled bentonite for enhanced detergent performance.

- Focuses on custom-formulated bentonite for industrial cleaners.

Why Chinese Bentonite is Popular in Detergents?

Cost-effective production and large-scale processing facilities.

Growing investments in high-quality sodium bentonite production.

Strategic export partnerships with detergent manufacturers worldwide.

4. India: A Key Supplier of Bentonite for Oil Detergents

India has significant bentonite reserves, particularly in Gujarat and Rajasthan, making it a major supplier of bentonite for industrial and household detergents. Indian manufacturers offer both sodium and calcium bentonite, catering to a diverse range of detergent formulations.

Key Indian Bentonite Suppliers for Oil Detergents

4.1 Ashapura Group

- One of the largest exporters of bentonite for detergent applications.

- Produces high-absorption bentonite for oil-based detergents.

- Exports to Europe, the Middle East, and Africa.

4.2 Kutch Minerals

- Specializes in low-dust, fine-milled bentonite for detergent production.

- Focuses on high-purity bentonite for liquid and powder detergents.

Why Indian Bentonite is Used in Detergents?

Large-scale production capacity and reliable global supply.

Competitive pricing and high product quality.

Customized bentonite formulations for different detergent applications.

5. Turkey: An Emerging Bentonite Producer for Detergents

Turkey has rich bentonite deposits, particularly in Anatolia, making it an emerging supplier for detergent manufacturers. Turkish producers focus on high-performance sodium bentonite with excellent absorption capabilities.

Key Turkish Bentonite Suppliers for Oil Detergents

5.1 Canbensan Bentonite

- Produces refined sodium bentonite for detergent applications.

- Focuses on eco-friendly bentonite for sustainable cleaning products.

5.2 KarBen Bentonite

- Specializes in custom-formulated bentonite for detergent manufacturers.

- Supplies low-dust bentonite for enhanced stability in liquid detergents.

Why Turkish Bentonite is Gaining Popularity?

High-quality sodium bentonite with strong absorption properties.

Strategic location for exports to Europe and the Middle East.

Growing investments in eco-friendly bentonite processing.

6. Iran: A Major Supplier for Middle Eastern Markets

Iran has abundant bentonite reserves, mainly in Semnan and Khorasan provinces, supplying regional detergent manufacturers. Iranian bentonite is widely used in industrial degreasers and oil-based cleaning agents.

Key Iranian Bentonite Suppliers for Oil Detergents

6.1 Iran Bentonite Co.

- Produces high-yield bentonite for oil detergent applications.

- Exports to GCC countries and Africa.

6.2 Sepehr Mine Group

- Specializes in refined bentonite for industrial detergent applications.

- Focuses on cost-effective, high-purity production.

Why Iranian Bentonite is in Demand?

Strategic location near detergent manufacturing hubs.

Affordable, high-quality bentonite for industrial and household use.

Expanding production facilities to meet global demand.

Future Trends in Bentonite for Oil Detergents

1. Rising Demand for Eco-Friendly Cleaning Products

- Development of biodegradable and low-impact bentonite-based detergents.

- Growing consumer preference for natural and sustainable cleaning solutions.

2. Technological Advancements in Bentonite Processing

- Nano-enhanced bentonite for improved absorption and cleaning power.

- Ultra-fine bentonite powders for enhanced performance in liquid detergents.

3. Expansion of Global Detergent Markets

- Increased demand for industrial degreasers and household oil cleaners.

- Emerging markets in Africa, South America, and Southeast Asia driving growth.

Conclusion: The Leading Producers of Bentonite for Oil Detergents

Bentonite remains a key ingredient in oil-based detergents, with major producers from the U.S., China, India, Turkey, and Iran driving the market. As global cleaning standards evolve, innovations in bentonite processing and sustainable detergent formulations will shape the industry’s future.

Key Takeaways:

The U.S. leads with high-quality sodium bentonite.

China and India dominate global bentonite exports.

Turkey and Iran are expanding production for the Middle Eastern market.

Technological advancements are enhancing bentonite’s detergent performance.

As demand for effective and eco-friendly cleaning solutions grows, bentonite will continue to play a crucial role in the detergent industry.

The Essential Role of Bentonite in Detergent Manufacturing