Description

Enhancing Glass and Ceramic Production with Bentonite

Bentonite: The Key Ingredient for

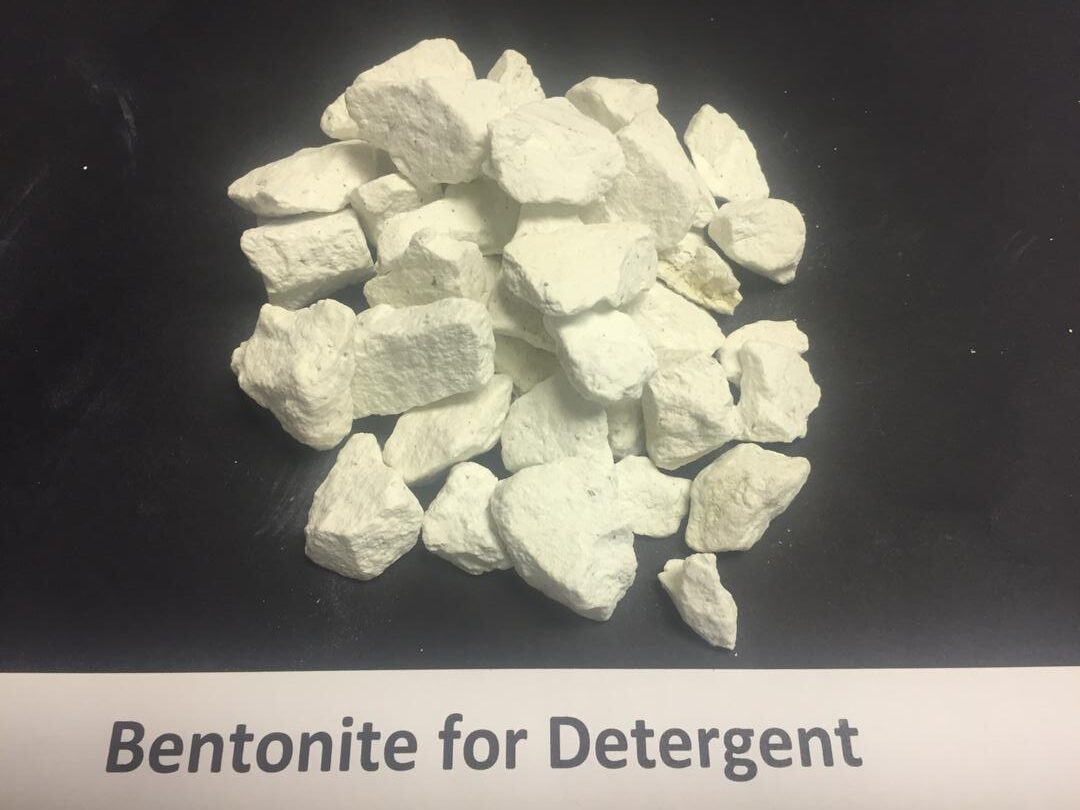

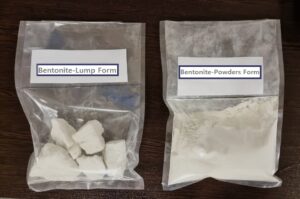

Glass and Ceramic Industries Bentonite, renowned for its unique properties and versatile applications, plays a crucial role in the glass and ceramic manufacturing processes. From enhancing plasticity to improving structural integrity, bentonit serves as a vital additive, ensuring superior quality and performance in glass and ceramic products. Bentonite for glass & ceramic.

Improving Plasticity and Workability

- Bentonit’s exceptional plasticity and rheological properties make it an ideal additive for glass and ceramic formulations. By increasing the workability of raw materials, bentonite facilitates shaping and molding processes, resulting in precise and intricate designs for glassware, tiles, and pottery.

Enhancing Binding and Adhesion

- In glass and ceramic production, bentonit acts as a binder, promoting adhesion between particles and components. Its adhesive properties help stabilize mixtures, ensuring uniform distribution of additives and preventing segregation during processing, resulting in homogenous and structurally sound products.

Controlling Shrinkage and Cracking

- Bentonite’s ability to control shrinkage and cracking is paramount in glass and ceramic manufacturing. By regulating moisture content and minimizing drying-related stresses, bentonite mitigates the risk of defects such as warping, distortion, and surface imperfections, ensuring dimensional stability and aesthetic appeal in finished products.

Improving Suspension and Settling

- As a colloidal stabilizer, bentonit prevents particle settling and sedimentation in glass and ceramic slurries. Its thixotropic nature imparts viscosity and suspension properties, allowing for uniform dispersion of solids and pigments, thereby enhancing color consistency, surface finish, and overall product quality.

Optimizing Firing and Sintering

- Bentonite’s high thermal stability and refractory properties make it an invaluable component in firing and sintering processes for glass and ceramic production. By acting as a flux and fluxing agent, bentonite promotes densification, fusion, and crystallization, facilitating the formation of durable and vitrified structures.

Partner with Us for Bentonite Solutions

Unlock the full potential of bentonite in your glass and ceramic manufacturing operations. As a trusted supplier of premium-grade bentonite products, we offer tailored solutions and technical expertise to meet your specific requirements. Contact us today to explore how bentonite can elevate the performance, efficiency, and quality of your glass and ceramic products.