Description

Bentonite for oil well drilling

Enhance Oil Well Drilling Efficiency with Bentonite Additives

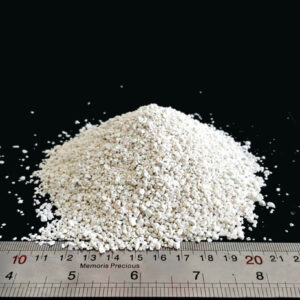

Bentonite:

The Key to Successful Oil Well Drilling Operations Bentonite, a natural clay mineral renowned for its exceptional properties, serves as a vital additive in the oil and gas industry. With its unique ability to create fluid muds, control viscosity, and enhance hole stability, bentonite plays a crucial role in optimizing drilling performance and ensuring successful oil well completion.

Fluid Mud Formation for Efficient Drilling

- Bentonite additives are used to create fluid muds, also known as drilling muds, which lubricate the drill bit and carry rock cuttings to the surface during drilling operations. By maintaining proper fluidity and density, bentonite-based muds facilitate efficient drilling, minimize downtime, and prevent costly drilling fluid losses.

Viscosity Control and Hole Stability

- One of the key functions of bentonite in oil well drilling is viscosity control. Bentonite additives help regulate the viscosity of drilling fluids, ensuring optimal flow properties while drilling through various geological formations. Moreover, bentonite contributes to hole stability by forming a protective filter cake on the wellbore walls, preventing formation damage and fluid invasion.

Lubrication and Friction Reduction

- In addition to providing viscosity control, bentonite acts as a lubricant, reducing friction between the drill string and the surrounding formations. This lubricating effect minimizes wear and tear on drilling equipment, extends tool life, and enhances drilling efficiency in challenging drilling environments.

Filtration Control and Formation Protection

- Bentonite-based drilling fluids help control fluid loss and filtration, preventing formation damage and ensuring wellbore integrity throughout the drilling process. By effectively sealing off porous formations and inhibiting fluid invasion, bentonite additives safeguard the productivity of oil and gas reservoirs, maximizing hydrocarbon recovery.

Versatile and Cost-Effective Solutions

- With its versatility and cost-effectiveness, bentonite is an indispensable component of oil well drilling fluids. From conventional rotary drilling to advanced directional drilling techniques, bentonite additives offer tailored solutions to meet the specific challenges of each drilling operation, ensuring optimal performance and cost savings.

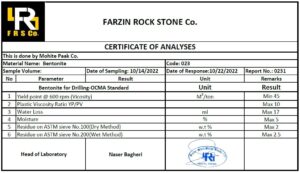

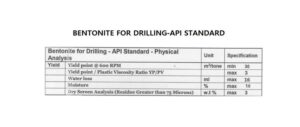

API13 Section 10, (non-treated bentonite) https://iranmineral.net/non-treated-bentonite/

Partner with Us for Superior Drilling Fluid Solutions

Experience the benefits of premium-quality bentonite additives for oil well drilling applications. As a trusted supplier of drilling fluid additives and specialty chemicals, we offer a comprehensive range of bentonite products designed to enhance drilling efficiency, productivity, and safety. Contact us today to learn more about how our bentonite additives can elevate your drilling operations.