The Premier Weighting Agent for Modern Drilling Operations

Introduction to Drilling Grade Barite

Drilling grade barite, also known as API barite, is a high-specific-gravity mineral predominantly composed of barium sulfate (BaSO₄). It plays an indispensable role in the global oil and gas drilling industry by acting as the primary weighting agent in drilling fluids — colloquially called “mud.” Its ability to increase fluid density without altering chemical properties makes it essential in managing downhole pressure and ensuring safe, efficient drilling operations. bdcinternational.com

“Barite’s unique density and chemical inertness make it the backbone of modern drilling fluid engineering,” says a drilling fluids specialist at DrillTech Insights, underscoring its central role in wellbore stability.

| Drilling grade barite, also known as API barite, is a high-specific-gravity mineral predominantly composed of barium sulfate (BaSO₄).One of the most defining properties of drilling grade barite is its specific gravity (SG).Barite is naturally chemically inert and insoluble in water and oil-based muds. |

What Makes Barite the Drilling Industry’s Choice?

High Specific Gravity & Weighting Efficiency

One of the most defining properties of drilling grade barite is its specific gravity (SG). API specifications dictate that high-quality drilling barite must have a minimum density of 4.1–4.2 g/cm³, enabling it to significantly boost the density of drilling fluids used to balance formation pressures. bdcinternational.com+1

This is critical because:

-

Higher fluid weight prevents sudden explosive influxes known as blowouts

-

Proper weighting controls formation pressures

-

Stable mud density enhances drill bit performance and borehole stability

Chemical Inertness & Low Reactivity

Barite is naturally chemically inert and insoluble in water and oil-based muds. This means it won’t react with other drilling fluid additives or downhole formations — a key quality that helps reduce mud chemistry complications and corrosion risk. SLB

Optimal Particle Size Distribution

API-compliant barite must have:

-

≤3% residue on a 75 µm wet screen

-

≤30% of particles finer than 6 µm

This ensures good suspension in mud and minimal abrasion to pump equipment. odmpllc.com

Barite Grades in the Market (4.0 – 4.3+)

API 4.1 & 4.2 Standards

The two most commonly supplied drilling barite grades today are:

-

Grade 4.1 – Meets base API requirements; suitable for standard drilling operations. siddachem.com

-

Grade 4.2 – Premium API compliance recognized for demanding drilling conditions and deep wells. siddachem.com

Special grades above 4.2 — such as 4.3 and above — are used for ultra-high-pressure / high-temperature (HPHT) operations where even greater density and performance are required. gilsonite-bitumen.com

Commercial Significance of 4.2 Grade Barite

Market research shows that Grade 4.2 barite holds a dominant share of global barite demand, representing roughly over 26% of total barite volume due to its optimized balance of density, performance, and cost. IMARC Group

The Role of Barite in Drilling Fluids

Hydrostatic Pressure Control

In drilling operations, fluid density must be high enough to counter formation pressures. Barite enables mud weights up to 20 lbs/gal (2.4 SG) and beyond without significantly increasing solid content — a crucial advantage in deep or unpredictable formations. nos-ly.nahroilservices.com

This translates directly into reduced risk of blowouts, fewer costly non-productive hours, and smoother drill bit penetration rates.

Wellbore Stability and Torque Reduction

Barite does more than add weight — its soft, inert nature reduces abrasive wear on downhole tools and pump components. Additionally, proper weighting distribution helps minimize stuck pipe incidents and borehole collapse, especially in unstable formations.

Barite Market Insights (Statistical Overview)

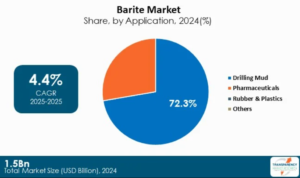

The barite industry is both large and expanding:

-

Drilling fluids account for ~80% of global barite consumption, estimated at 5.9 million tons in 2024. Market Growth Reports

-

The barite market was valued at approximately US$1.5 billion in 2024 and is projected to grow to US$2.4 billion by 2035 at a CAGR of ~4.4%. transparencymarketresearch.com

-

India and the United States are major producers, with India alone producing roughly 1 million tons annually. Market Growth Reports

Industry analysts from Global Mineral Insights note: “The drilling segment will continue to dominate barite demand due to ongoing global exploration and unconventional drilling trends.”

Commercial Benefits of High-Quality Drilling Barite

Optimized Rig Performance

High-grade barite that meets API standards ensures:

-

Consistent hydrostatic pressures

-

Reduced mud system instability

-

Lower operational costs due to reduced additives

Versatility Across Drilling Conditions

Drilling grade barite can be used in:

-

Water-based mud systems

-

Oil-based mud systems

-

Synthetic based drilling fluids

This versatility gives drilling engineers flexibility and cost savings in fluid design and deployment.

Cost Efficiency

Because barite requires minimal chemical reactivity and pump power to disperse, its use often translates into lower operational costs, reduced downtime, and less waste. These advantages make barite a commercially attractive component in drilling budgets.

Why Choose Certified API Barite for Your Operations

If your drilling project demands reliability and performance, choose barite that is:

✔ API 13A compliant

✔ Processed to meet particle size distribution standards

✔ High in specific gravity (≥4.1 – 4.2)

✔ Low in soluble contaminants (≤250 mg/kg) odmpllc.com

These characteristics help ensure dependable drilling fluid performance, fewer equipment issues, and upstream cost savings.

Supply Chain & Procurement Tips

When sourcing drilling grade barite:

1. Verify API Certification

API compliance ensures consistency and performance you can trust.

2. Check Particle Size and Bulk Density

These affect how the barite interacts with your drilling fluid system.

3. Compare Purity & Impurities

Lower contaminant levels improve fluid stability and reduce chemical waste.

4. Ensure Reliable Logistics

Local availability and bulk shipping options can significantly lower costs.

Conclusion

Drilling grade barite is far more than a mineral — it is a strategic drilling fluid additive that directly influences wellbore stability, downhole pressure management, and overall operational efficiency. With strong market growth, global demand predominantly driven by the oil and gas industry, and stringent API standards guiding quality, barite remains the go-to weighting agent for drilling engineers worldwide.

Investing in high-quality drilling grade barite — especially API 4.2 grade — is not just prudent; it’s essential for safe, cost-effective, and productive drilling operations.